Pumps for Spraying

Spray pumps are special devices designed to spray liquid solutions or mixtures onto the surface of plants, soil or other objects. They are widely used in agriculture to treat fields with pesticides, herbicides and fertilisers, as well as in horticulture and landscape design to care for plants. Industrial spraying pumps are distinguished by their high performance, precise spraying and reliable operation. They can be equipped with various nozzles and pumping systems depending on the specific application and processing requirements.

TOP-10 Pumps for spraying + other products

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

Multi-Function Electromagnetic dosing pump

Valisi electromagnetic metering pumps are suitable for dosing of all types of liquid products. All pumps are diaphragm pumps, which means they accurately dispense small, constant volumes of liquids or chemicals. In addition, their hermetic design allows them to self-drain after use, reducing the risk of leaks and clogging.

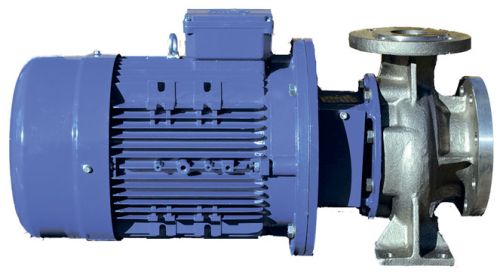

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

In-line centrifugal pumps

Сlose coupled industrial pumps of the NCL series - IN LINE design - are units designed to support technological processes involving the pumping of hazardous liquids. The main field of application of such equipment is the petrochemical and chemical industries. The pumps are indispensable for solving such tasks as pumping acids, caustics, chlorine alkaline solutions, chemical fibers, polymers, volatile organic compounds, sludge pumping and waste treatment. The pumps are CE-marked and comply with applicable European directives such as ATEX.

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Spraying pumps

Spraying pumps are specialized devices designed to spray various liquids onto the surface of plants, soil or other objects. They are widely used in agriculture, horticulture, landscape design and industry for plant treatment and protection, as well as for applying fertilizers and chemicals.

Advantages of industrial spraying pumps

Industrial spraying pumps are characterized by high performance, reliability and durability. They are designed to provide uniform and effective spraying of liquids over large areas, which allows you to significantly increase productivity and reduce resource costs.

Variety of spray pump models

There are many different models of spray pumps on the market, from compact portable devices to large stationary installations. Each model has its own unique characteristics, such as performance, power, type of nozzles used and control systems. When choosing a pump, it is necessary to take into account the specifics of the specific task and processing requirements.

Application of spray pumps in agriculture

In agriculture, spray pumps play an important role in the processing of fields and the care of cultivated plants. They are used to apply pesticides, herbicides, insecticides and other chemicals to protect plants from pests and diseases, as well as to apply fertilizers and growth regulators.

Applications of Spray Pumps in Horticulture and Landscape Design

In horticulture and landscape design, spray pumps are used to care for lawns, flower beds, shrubs and other plants. They help fight weeds, pests and diseases, ensuring a healthy and beautiful appearance of plants.

Choosing a spray pump

When choosing a spray pump, it is necessary to take into account not only its technical characteristics, but also the features of its operation, the requirements for the treated surfaces, the type of chemicals used, and the operating conditions. It is also important to pay attention to the brand and reputation of the manufacturer to be sure of the quality and reliability of the selected equipment.