Pumps for Dewatering

Dewatering pumps are specialised equipment for removing water from rooms or areas. They are widely used in construction, industry, agriculture and emergency situations where fast and efficient water removal is required to prevent damage to buildings, equipment or crops. Dewatering pumps are highly productive, reliable and can be operated both automatically and manually, making them an important tool for ensuring the safety and efficiency of work processes.

TOP-16 Pumps for dewatering + other products

Single stage liquid ring vacuum pumps AVM & AVL

The AVM and AVL series consist of single-stage liquid ring vacuum pumps designed to achieve deep vacuum. Both series have the same hydraulics but different designs.

Dry Screw Pumps AVVS series

AVVS series consists in dry screw vacuum pumps designed tooperate at very deep vacuum capable to achieve 0,05 mbar or deeper if combined with a booster pump. The new patented hybrid screw design ensures higher efficiency due to lower temperature and less power consumption. Different type of coatings protect the internals from corrosion caused by aggressive gas mixture and vapors typical of the process industry, chemical, pharmaceutical and petrochemical applications.

Liquid ring pump condenser exhausters

Liquid ring vacuum pumps are used in centralised vacuum systems and in power generation. The vacuum systems consist of exhaust ventilation units for the main condenser and filling units for the water condenser. The systems are designed for both load and hold modes.

In many cases, the pump is assisted by a first stage gas or steam ejector to improve pump performance at different condenser loads. The ASCO VACUUM team has extensive experience in geothermal applications.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

Vertical centrifugal pumps

You can buy centrifugal vertical single-stage pumps of the NCV series from ASCO PUMPS Ukraine. The maximum shaft length is 5 m. The standard design is designed for rotational speeds up to 2900 rpm. The radial bearings are lubricated by the pumped liquid, provided it does not contain any suspended abrasive particles. If the pumped fluid is slightly abrasive, the radial bearings are lubricated with an external special transparent grease.

Sanitary centrifugal stainless steel pump LT series

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Two-stage liquid ring vacuum pumps of the AVD series

Two-stage vacuum pumps of the AVD-AVDL series are capable of creating a maximum residual pressure of up to 33 mbar. They are in demand in cases where it is necessary to pump out various moisture in the form of steam or liquids in sufficiently large quantities. The reliability of the products is beyond doubt, they are easy to maintain, and they can be used to pump out any gas or vapour. Materials used for manufacturing range from high-quality, particularly resistant cast iron to stainless steel of the highest grades, for example, AISI 316.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

ANSI UC Sealless Pumps

Designed for use in the most extreme chemical processing applications, the ULTRAChem® series pumps are magnetically driven pumps that meet ANSI standards. The pumps are designed for pumping aggressive, chemically active liquids. The concentration of suspended solids should not exceed 1.25 mg/cubic cm. The pumps are ideal for operation at ultra-low ambient temperatures.

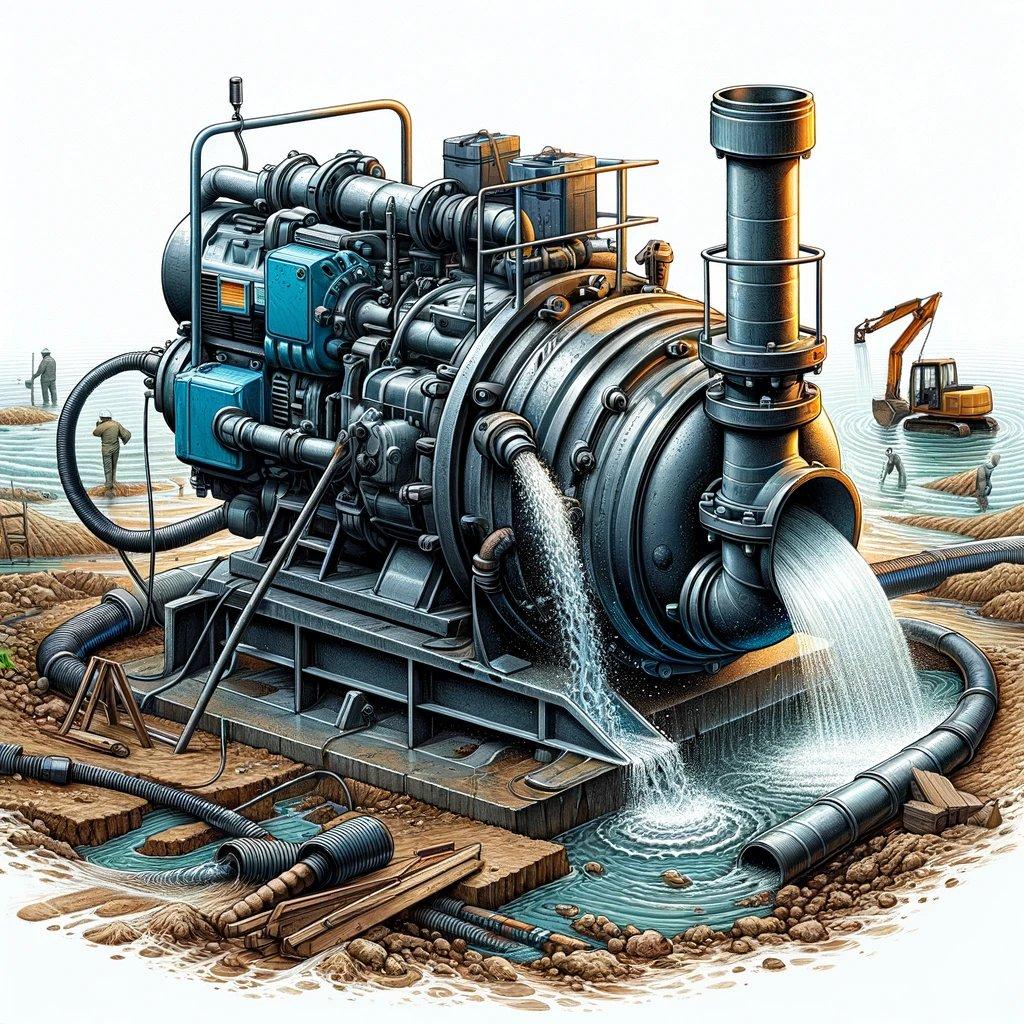

Dewatering pumps

Dewatering pumps are an integral part of equipment in various industries, construction and emergency situations. They are designed to quickly and effectively remove water from various surfaces, rooms and areas. Dewatering pumps have a wide range of applications and can be used both to prevent floods and to maintain dryness on construction sites, basements and sewage systems.

Advantages of industrial dewatering pumps

Industrial dewatering pumps are characterized by high performance, reliability and durability. They are designed to work in difficult conditions and are able to work effectively for a long time without failures. In addition, many models of industrial pumps are equipped with automatic control systems, which ensures convenience and safety in operation.

Choosing a pump for dewatering

When choosing a pump for dewatering, a number of factors should be taken into account, including the volume of water being pumped, the type of energy source used, the depth of the water source and the specific operating conditions. It is also important to pay attention to the performance and energy efficiency of the pump, as well as its reliability and durability.

Applications of Dewatering Pumps

Applications of Dewatering Pumps

Dewatering pumps are widely used in construction, mining, agriculture, municipal services and emergency situations. They can be used to pump water from basements, sewer systems and tunnels, as well as to combat floods and leaks in water supply systems.

As a result, dewatering pumps are indispensable equipment for maintaining dryness and safety at work sites, as well as preventing damage from floods and leaks. Choosing the right pump for your specific needs and operating conditions will help ensure efficient and uninterrupted water removal in any situation.