Pumps for Filtration

Filtration pumps play an important role in a variety of industries and domestic applications, ensuring the effective removal of contaminants from liquids or gases. These pumps are used in water purification systems, wastewater treatment, water supply, as well as in the chemical, food and pharmaceutical industries. Industrial filtration pumps are highly productive and reliable, capable of operating in a variety of conditions and pumping liquids with a high content of solids or aggressive substances. They can be equipped with special filters and separators for more efficient media treatment. The selection of the right filtration pump depends on many factors, including the type and concentration of contaminants, performance, pressure and flow requirements, and the specific process or system requirements.

TOP-26 Pumps for filtration + other products

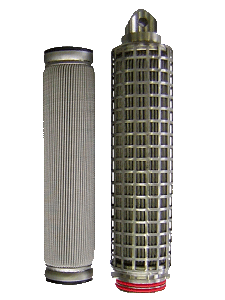

SC: Single cartridge medium pressure

Technical specifications

Type: single cartridge "Standard"

Material: polished steel AISI 316 / AISI 304

Seals: EPDM, Buna N, silicone, Viton, PTFE, FEP

Volume (l): 0.95 - 10.7

Max. working pressure (bar): 25

Drainage: 1/4" GAS-F

Max. operating temperature (°C): 100

Connections: 3/4" GAS-F, 1 1/2" GAS-F

HC: Single cartridge low pressure

Technical specifications

| Type: single cartridge "Standard" Material: polished steel AISI 316 / AISI 304 Seals: EPDM, Buna N, silicone, Viton, PTFE, FEP Volume (l): 0.95 - 10.7 Max. working pressure (bar): 25 Drainage: 1/4" GAS-F Max. operating temperature (°C): 100 Connections: 3/4" GAS-F, 1 1/2" GAS-F |

SCT: Single cartridge high pressure

Technical specifications

| Type: single cartridge ‘High Pressure’ Material: polished steel AISI 316 / AISI 304 Seals: EPDM, Buna N, silicone, Viton, PTFE, FEP Volume (l): 1.2 - 5.7 Max. working pressure (bar): up to 69 Drainage: 1/2 GAS-F Max. operating temperature (°C): 100 Connection: 1 1/2’ GAS-F - 3’ GAS-M |

MCR: Multiple cartridge low pressure

Technical specifications

| Type: multicartridge Material: polished steel AISI 316 L Seals: EPDM, Buna N, silicone, Viton, PTFE, FEP Volume (l): 0.95 - 10.7 Max. working pressure (bar): 25 Drainage: 3/8’ GAS-F Max. operating temperature (°C): 80 Connections: 1’ NPT-F |

HF-LF: Hy-flow and large flow low pressure

Technical specifications

| Type: cartridge (1 to 3 pieces) - high throughput Material: electropolished steel AISI 316 L Gaskets: EPDM, silicone, Viton, FEP, PTFE Volume (l): 9 - 140 Max. working pressure (bar): 8 bar at 80 °C (V-Clamp); 10 bar at 100 °C (Rathmann) Drainage: 1/2'' GAS-F Max. operating temperature (°C): 100 Connections: 1'' NPT-F to DN 150 flange (PN16) |

BFR, BFF, BTF Single bags low pressure

Technical specifications

Type: bag type

Material: polished steel AISI 316 L / AISI 304

Seals: EPDM, silicone, viton, FEP

Volume (l): 2.6 - 28

Capacity (m3/h): 9 - 35

Max. working pressure (bar): 8

Drainage: 3/8’, 1/2’ GAS-F

Max. operating temperature (°C): 100

Connections: 1 1/2’ - 3’ GAS-M

MT: Multiple cartridges medium-low flow-rate

Technical specifications

|

Type: medium and low flow multi-cartridge |

ST: Basket custom made

Technical specifications

| Type: basket type Material: carbon steel, stainless steel, other materials on request Seals: Buna N, KlingerSil, Viton, FEP, PTFE Capacity (m3/h): up to 10,000 Max. operating pressure (bar): 16 Max. operating temperature (°C): 100 Connections: 1 ½’ GAS-F to DN 150, flange (PN16) Standards: according to 97/23/CE, 94/9/CE Accessories: differential pressure gauge, differential pressure switch, vent valve, drain valve, pressure safety valve |

MBW: Self-Cleaning filters

Technical specifications

| Type: self-cleaning filter Material: carbon steel, stainless steel, 5% alloy steel Sealing: KlingerSil, spiral wound gasket Capacity (m3/h): up to 1000 Connection: up to 16’ (DN 400) Standards: ASME Sect. VIII Div. 1, EN 13445, VSR Accessories: pressure gauges, differential pressure transmitters, safety valve, drain valve, insulation |

MB: Nominal PP Melt-blown

Technical specifications

| Max. operating temperature (°C): 80 |

| Material: polypropylene |

| Seals: EPDM, Buna N, silicone, Viton |

| Max. operating pressure (bar): 4.2 |

| Inner diameter: 1.1’ (28 mm) |

| Outer diameter: 2.5’ (63 mm) |

|

Length: 10‘, 20’, 30‘, 40’, 50’, 60’ |

FV: Paper/Fibre glass pleated

Technical specifications

Max. operating temperature (°C): 160

Filter material: resin-impregnated paper, fibre glass

Seals: EPDM, Buna N, silicone, Viton

Max. operating pressure (bar): 5

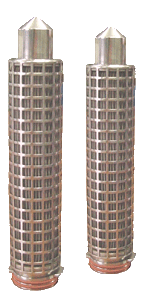

WM: Wire mesh

Technical specifications

Outer diameter 2.4‘ (60 mm) corrugated; 2.5’ (63 mm) bonded;

2.7’ (68 mm) welded.

Inner diameters 1.0‘ (26 mm), 1.4’ (36 mm) (code 9 only).

Lengths 10‘, 20’, 30‘, 40’.

Filtration area: pleated 0.20 m2 x 10‘, cylindrical 0.05 m2 x 10’.

Degree of filtration: from 5 to 1000 μm.

HYD: Pleated Depth

Technical specifications

Outer diameter 2.7’ (68 mm).

Inner diameter 1.1‘ (28 mm), 1.4’ (36 mm) (code 9 only).

Lengths 10‘, 20’, 30‘, 40’, 50‘, 60’.

Working area for filtration: 10 ‘: 0.18 м2, 20": 0.36 м2,

30 ‘: 0.54 м2, 40": 0.72 м2, 50 ‘: 0,90 м2, 60": 1,08 м2.

The degree of filtration: from 1.0 to 50 μm.

MNN: Nylon Melt-blown

Technical specifications

Outer diameter 2.5’ (63 mm).

Inner diameter 1.1‘ (28 mm), 1.0’ (25 mm).

Length 10‘, 20’, 30‘, 40’.

Filtering area: 10 ‘: 0.05 м2, 20": 0.10 м2,

30 ‘: 0.15 м2, 40": 0.20 м2.

The degree of filtration: from 1.0 to 100 μm.

PO-PE: Felt

Bag filtration is an economical and valid alternative to cartridge filtration. Dirt remains inside of the bag that is easy to change and dispose of. The range includes different solutions to satisfy also the most.

SF: Sintered fibres

Technical specifications

Outer diameter 2.4‘ (60 mm) corrugated; 2.7’ (68 mm) welded.

Inner diameter 1.0‘ (26 mm), 1.4’ (36 mm).

Lengths: 10‘, 20’, 30‘, 40’.

Filtering area: 10 ‘: 0.13 м2, 20": 0.26 м2, 30 ‘: 0.39 м2, 40": 0.52 м2.

The degree of filtration is from 3 to 75 μm.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

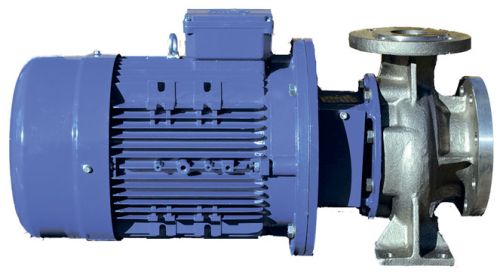

Closed coupled centrifugal pumps

With pump ends conforming to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria, the NCB provides a compact, space-saving arrangement ideal for industrial processes or installations when space is at a premium. NCB pumps are fitted with standard, readily available electric motors so the user can choose an enclosure to suit the application.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads.

CM monobloc pump series

CMA series pumps are open impeller pumps designed for pumping liquids with suspended solids and solid particles. CMC series pumps are pumps with a closed impeller made of two stainless steel disks. CMA/CMC series pumps are used for transportation of large volumes of chemically active liquids and acids, for petroleum products, in galvanizing, pharmaceutical and paint and varnish industries.

Motor speed gear pumps

Viking's motor-speed industrial pumps are designed for increased performance by using double ball bearings and a direct motor-pump arrangement. Reliable mechanical seals and gaskets eliminate leakage and extend pump life.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Filter pumps

Functional purpose of pumps

Filter pumps play a key role in the processes of cleaning and filtering liquids and gases in various industries and domestic conditions. They provide effective removal of contaminants and solids from the environment, improving the quality of water, oil, chemical solutions and other liquid media.

Applications of filtration pumps

Industrial filtration pumps are used in a wide range of industries, including water treatment and wastewater treatment, food and beverage industry, chemical production, pharmaceuticals, oil and gas industry and many others. They are used for water purification from water intake and treatment facilities, oil filtration in automotive and industrial equipment, as well as for the removal of solids from liquid media in various technological processes.

Characteristics of filtration pumps

Industrial filtration pumps have different characteristics, such as performance, pressure, material of the housing and working parts, dimensions and type of connection. They can be equipped with various types of filters and separators that provide optimal purification of the medium from various contaminants.

Choosing a pump for filtration

Choosing a pump for filtration

When choosing a pump for filtration, it is necessary to take into account a number of factors, including the characteristics of the pumped medium, performance requirements, pressure and flow, as well as the features of a particular process or system. It is also important to consider the operating conditions, temperature and chemical parameters of the medium, as well as the degree of purification required to achieve the required product quality or ensure the efficiency of the production process.