Pumps for Dual dispensing

Dual metering pumps are specialised equipment used for the precise and controlled dosing of two different liquids or reagents. They are widely used in industry, pharmaceuticals, water treatment, food processing and other sectors where precise mixing of two components with a certain proportion is required. Double dosing pumps provide high accuracy and stability of the dosing process, which allows you to achieve the required quality of the final product or result. They also come with a variety of functions and customisation options, making them a versatile and reliable solution for a variety of dosing applications.

TOP-5 Pumps for dual dispensing + other products

Valisi dosing pumps VD-EСА

The Valisi VD-ECA series are diaphragm and piston metering pumps with advanced metering control for precise and automatic control. The pumps are designed to accommodate a variety of remote control options such as SCADA, etc.

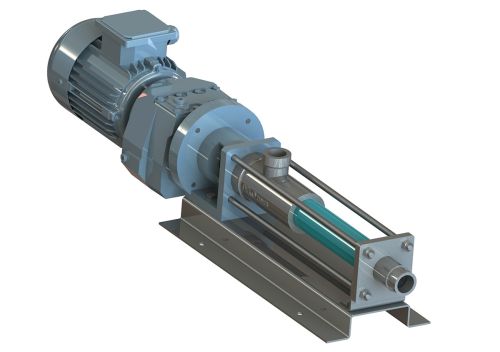

Screw dosing pump

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

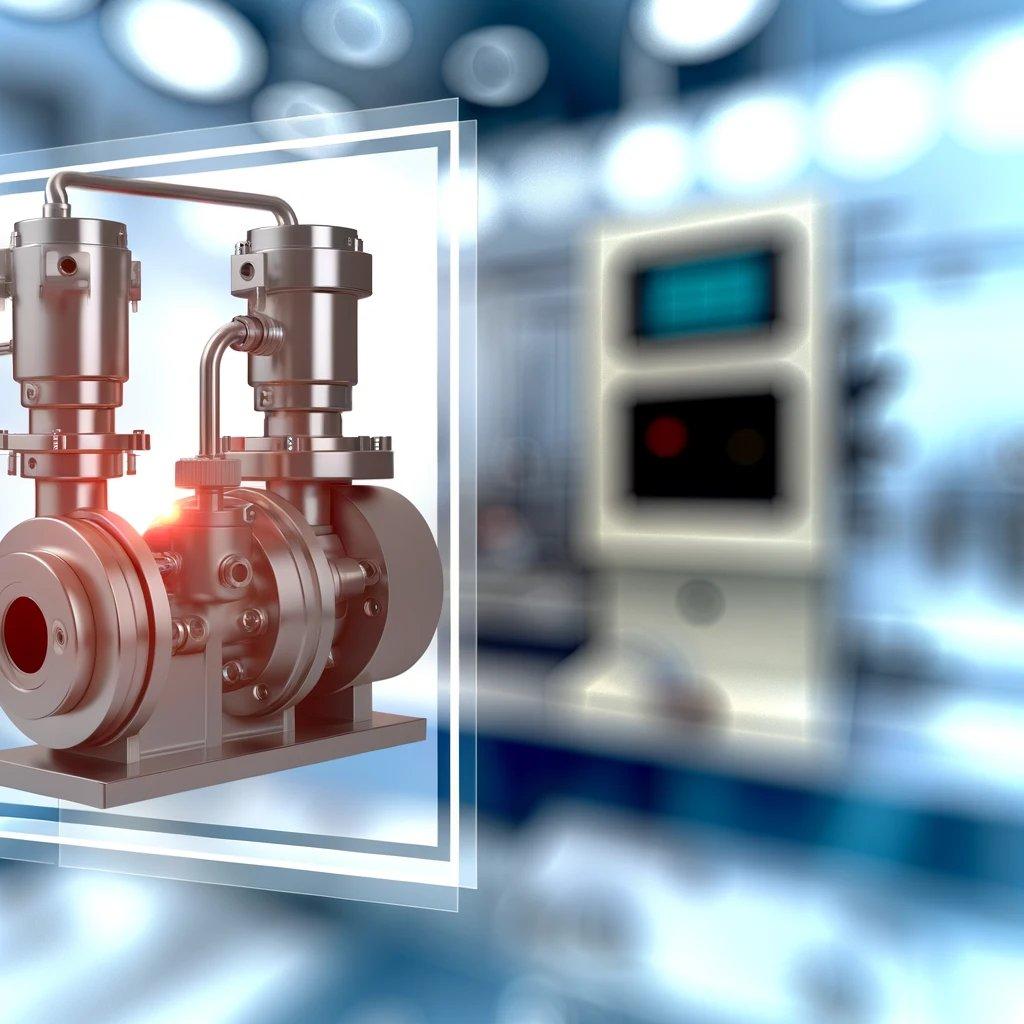

Valisi dosing pumps VD-EMP

Electric metering pumps (piston and diaphragm) are designed for maximum operating ranges. Diaphragm and piston dosing pumps are specially designed for dosing all types of chemicals, whether corrosive, toxic or highly viscous, for water treatment, industrial processes, petrochemicals and agriculture. The main advantage of the pumps is the ability to connect up to four working heads to one motor, and these units can simultaneously pump different types of liquids with different capacities. The pumps themselves are made of high-quality materials, have a robust design and are maintenance-free.

Double dosing pumps

Double dosing pumps are modern technical solutions designed specifically for the accurate and reliable dosing of two different liquids or reagents. These pumps have found wide application in various industries due to their high efficiency and reliability.

Functional capabilities

Industrial double dosing pumps have various functional capabilities that allow you to precisely control the process of feeding two liquids. They are equipped with special control systems that ensure high dosing accuracy even for larger volumes.

Industrial applications

These pumps are widely used in various industries, such as chemical, pharmaceutical, food and many others. They are used for the production of products that require precise mixing of two components, as well as for the automation of dosing processes in production.

Accuracy and reliability

Double dosing pumps are characterized by high accuracy and reliability. They are able to deliver two liquids with certain proportions, which avoids unnecessary material consumption and ensures stable quality of the final product.

Parameter settings

Industrial double dosing pumps are usually equipped with various settings that allow you to change the parameters of the liquid feeding process according to production requirements. This makes them a versatile solution for various dosing tasks.

Benefits of Use

The use of dual dosing pumps has a number of advantages, including saving time and resources, increasing process productivity, and improving the quality of the final product. In addition, they ensure more efficient use of materials and reduce the likelihood of dosing errors.

Conclusion

Dual dosing pumps are essential equipment for industrial enterprises where accurate and reliable dosing of two different liquids is required. They provide high accuracy and stability of the dosing process, making them an indispensable tool in the production of various products and materials.