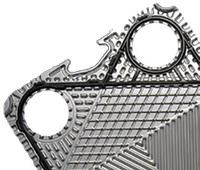

Plates for plate heat exchangers

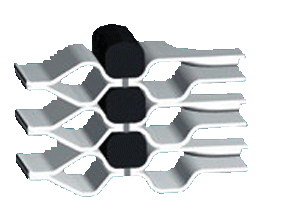

ParaWeld - welded pairs of plates

The APV® ParaWeld heat exchanger consists of plates welded in pairs using a patented laser welding process. Every other channel is welded, while the remaining channels are gasketed. The welded channels make it possible to handle aggressive and complex media in plate heat exchangers.

EasyFlow plate type

EasyFlow plates offer minimal hydraulic resistance. The plates have a larger channel cross-section and fewer contact points and are used for media containing fibers or cellulose, for viscous media and emulsions. They provide a minimum temperature head.

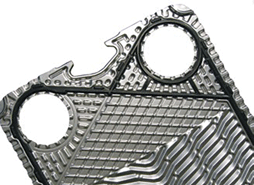

EnergySaver plate type

The plates provide the highest thermal performance, the channels have the maximum number of plate contact points, and the channel diameter is 6.2 mm.

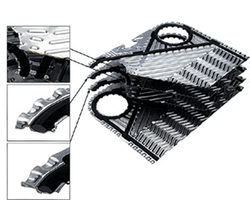

DuoSafety plate type

DuoSafety - Double wall plate design for reduced risk of intermixing.

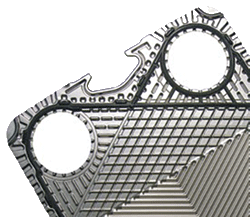

DuraFlow plate type

DuraFlow plates provide low hydraulic resistance, the channels have an average number of plate contact points, and the channel diameter is 9.3 mm. It has an advantage in case of high temperature head, low permissible hydraulic resistance, and in the use of viscous media.

- DeliveryWe guarantee a prompt and reliable delivery of pumping equipment to any part of the country.

- InstallationWe guarantee a high quality installation work, which ensures optimal and safe operation of the pumping equipment.

- WarrantyWe provide an extended warranty period for all pumping equipment, which indicates its high quality and reliability.

Why us

6 advantages of co-operating with us for the supply of industrial pumps

- High quality products

- Our company supplies industrial pumps from the world leading manufacturers. We guarantee the high quality of our products, which is confirmed by many successful projects and positive feedback from our Customers. Our pumps are highly reliable, durable and efficient, which ensures uninterrupted operation at your production facilities.

- Personal approach

- We understand the uniqueness of each order and offer customised solutions tailored specifically to the technical requirements and wishes of each customer. Our specialists are ready to provide advice, conduct technical analysis and select the most suitable type of pumping equipment.

- Service and technical support

- In addition to supplying equipment, we offer a full range of maintenance and repair services. Our qualified engineers are ready to come to the site promptly to eliminate malfunctions, which minimise downtime.

- Flexible terms of cooperation

- We strive to make cooperation with us as convenient and profitable as possible for you. In this context, we offer flexible delivery terms, including prompt order fulfilment and the ability to choose a convenient delivery method.

- Wide range of products

- Our catalogue contains a wide range of industrial pumps of various types and modifications, which allows us to meet the needs of almost any production process. From pumps for general industrial use to specialised solutions for specific industries, we have it all.

- Environmental responsibility

- We recognise the importance of environmental safety and strive to minimise our impact on the environment. The pumps we supply comply with all the latest environmental standards and requirements, enabling our customers to not only optimise their production processes but also contribute to environmental protection.

Articles

The last news and articles

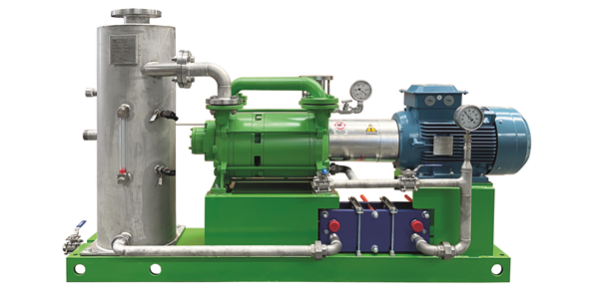

Monoblock liquid ring vacuum pumps driven by permanent magnet motors

More details

Aquapack systems with double stage pump

More details