Abrasion resistant pumps

Abrasion-resistant pumps are reliable and durable equipment specially designed to handle aggressive and abrasive media. They have a high degree of wear resistance thanks to the use of special materials and design solutions, making them the ideal choice for applications that require high wear resistance and long service life. These pumps are widely used in a variety of industries, as well as in agriculture and municipal services, where reliable and efficient equipment is required for pumping aggressive and solid media. Abrasion-resistant pumps provide stable and trouble-free operation in harsh environments, making them an important element in production and technical processes in various industries.

TOP-6 Abrasion resistant + other products

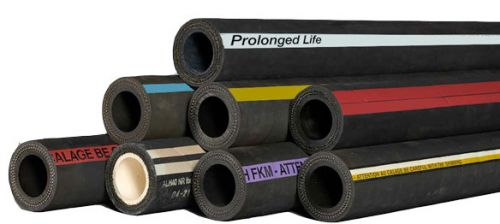

Hoses

We offer a wide range of hoses for peristaltic pumps. Our hoses are specially designed to last longer and perform better than the competition, resulting in reduced maintenance and downtime. The type of polymer and mechanical properties of the hose are the main factors for proper pump operation. The performance of a hose is determined by its elasticity, long-term resistance to compression and its chemical compatibility with the fluid being pumped.

Vertical centrifugal pumps

You can buy centrifugal vertical single-stage pumps of the NCV series from ASCO PUMPS Ukraine. The maximum shaft length is 5 m. The standard design is designed for rotational speeds up to 2900 rpm. The radial bearings are lubricated by the pumped liquid, provided it does not contain any suspended abrasive particles. If the pumped fluid is slightly abrasive, the radial bearings are lubricated with an external special transparent grease.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

Side Channel Blowers

Blowers are an excellent choice for many automated projects where the application requires large volumes of clean, dry air at low pressure and vacuum. We strive to provide a solution that allows for easy installation, yet provides low operating noise and energy savings in a small, lightweight design.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Abrasion-resistant pumps

Abrasion-resistant pumps are high-quality equipment that can operate effectively in conditions of increased wear and abrasiveness of the environment. They are distinguished by special design solutions and the use of wear-resistant materials, which ensures their long service life and reliability in operation.

Advantages of abrasion-resistant pumps

- Durability: thanks to special materials and design, the pumps are resistant to wear and provide a long service life without loss of efficiency.

- High performance: they are able to work with abrasive media without reducing performance, which makes them an ideal choice for industrial applications.

- Reliability: abrasion-resistant pumps offer reliable operation even in the most difficult operating conditions, which reduces the risk of downtime and accidents.

Industrial Applications

These pumps are widely used in various industries:

- Mining industry: abrasion-resistant pumps effectively pump abrasive ores and materials.

- Cement production: they ensure reliable supply of cement and other abrasive materials in the production process.

- Waste treatment: abrasion-resistant pumps are widely used in waste treatment and pumping systems.

Choosing abrasion-resistant pumps

When choosing such pumps, attention should be paid to their performance, the type of materials used, the class of protection against aggressive environments and the appropriate type of drive. It is recommended to contact professional consultants to select the optimal equipment for specific operating conditions.