Adjustable flow pumps

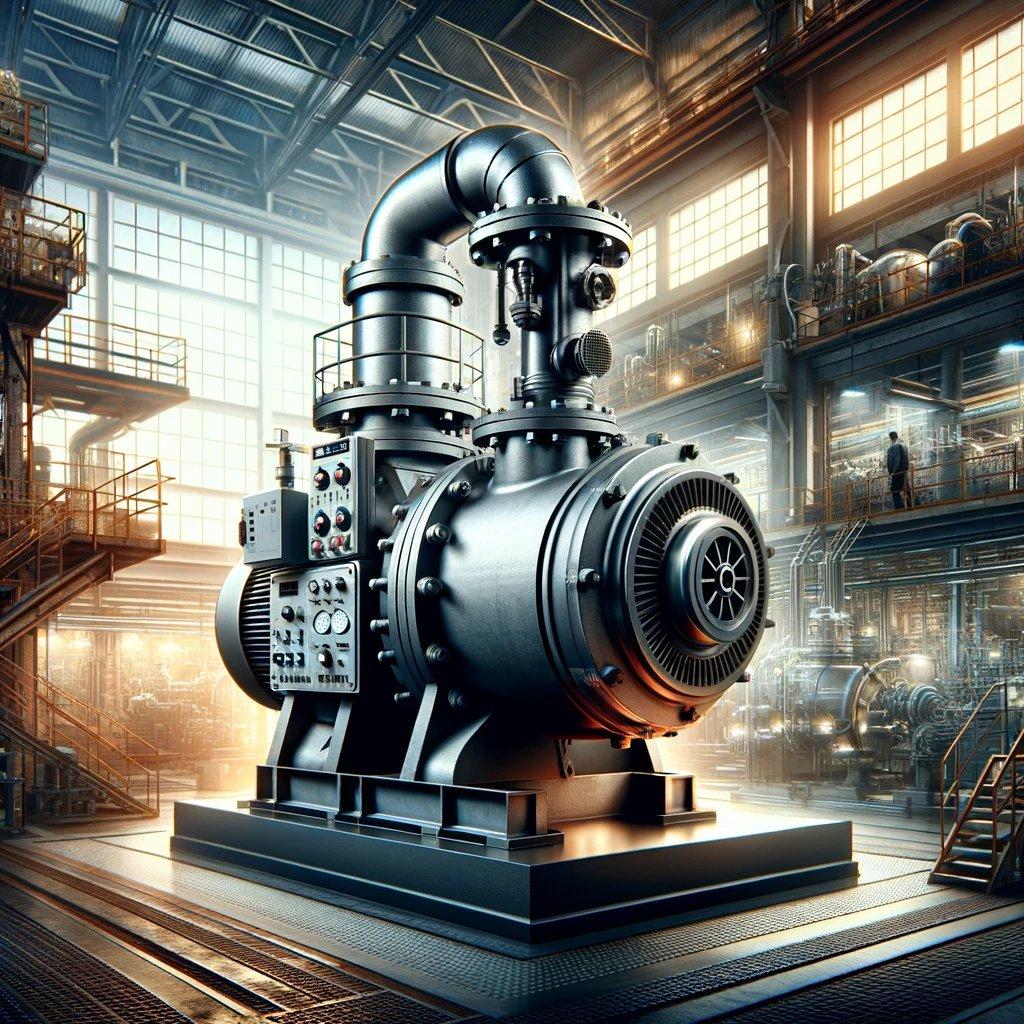

Adjustable flow pumps are essential equipment for many industries that require precise control of liquid or gas flow. These pumps provide the ability to adjust the volume of the medium to be pumped depending on the current process requirements. This flexibility allows them to optimise production processes, save energy and ensure stable system operation. Industrial variable displacement pumps are highly efficient, reliable and have a long service life, making them a popular choice for a variety of industrial applications.

TOP-11 Adjustable flow + other products

Multi-Function Electromagnetic dosing pump

Valisi electromagnetic metering pumps are suitable for dosing of all types of liquid products. All pumps are diaphragm pumps, which means they accurately dispense small, constant volumes of liquids or chemicals. In addition, their hermetic design allows them to self-drain after use, reducing the risk of leaks and clogging.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

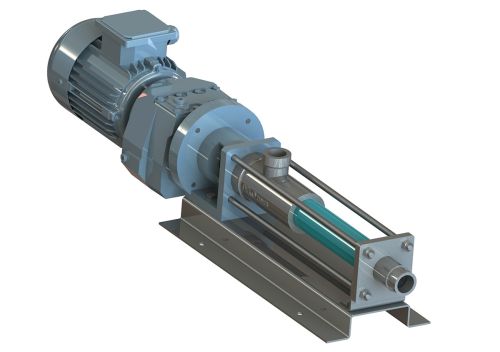

Screw dosing pump

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

All-welded plate heat exchangers SIGMAWIG

The line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many demanding industrial applications.

This is a new level of application for heat exchangers for special applications in the chemical and pharmaceutical industries, industrial cooling systems and heat balance systems.

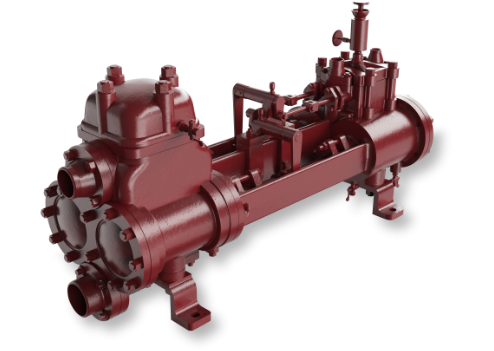

Steam driven reciprocating pumps (API 674)

Since the beginning of the last century, Peroni has been designing and manufacturing steam driven pumps used for boiler feed service, low NPSHA pump-out service and for other process applications in Petrochemical Plants and in Refineries. All Peroni steam driven pumps are reciprocating, horizontal duplex, double-acting pumps where the power is directly transmitted to the liquid end by the action of the motive fluid on the piston. The motive fluid is normally steam, but can also be air or gas.

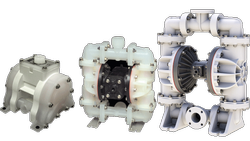

Valisi metallic series V

Valisi metal pumps of the V series are available in a variety of construction materials: aluminium and stainless steel. This series of pumps for industrial applications provides high efficiency and reliability for continuous operation. With a flow rate of up to 908 l/min and a wide variety of materials and channel configurations, you will find the right pump for your application. FDA-compliant metal pumps are available, specially manufactured from materials that are safe for food, beverage, pharmaceutical and cosmetic processes where 3A, USDA or EHEDG standards are not required. The simple, robust design features trouble-free air valve operation, oil-free operation, reliable on/off operation, easy operation and maintenance, and delicate/shear-sensitive product handling. The pumps comply with EU Directive 1935/2004.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Adjustable Flow Pumps

Adjustable flow pumps are efficient and reliable equipment used in various industries to precisely control the flow of liquids or gases. These pumps provide the ability to adjust the volume of the pumped medium depending on the current process needs, making them an ideal choice for many production tasks.

Industrial Adjustable Flow Pumps

Industrial Adjustable flow pumps are characterized by high efficiency, reliability and long service life. They are designed to ensure stable and accurate system operation, as well as minimize energy and resource losses. Thanks to their flexibility and the ability to precisely adjust the flow, these pumps allow you to optimize production processes and save on equipment operating costs.

Regular flow pump

An adjustable flow pump has a wide range of options for adjusting and controlling the flow of a liquid or gas. It can be used in various industrial sectors, such as the chemical industry, oil and gas industry, food industry and others. Flexible settings allow you to accurately meet the requirements of a specific process and ensure high efficiency of the system as a whole.

An adjustable flow pump has a wide range of options for adjusting and controlling the flow of a liquid or gas. It can be used in various industrial sectors, such as the chemical industry, oil and gas industry, food industry and others. Flexible settings allow you to accurately meet the requirements of a specific process and ensure high efficiency of the system as a whole.

The choice of adjustable flow pumps is key to ensuring the efficient and stable operation of technological processes. Professional industrial pumps of this type provide high performance, resource savings, and system reliability throughout the entire service life.