Submersible pumps

Submersible pumps are an effective solution for pumping liquids from deep sources such as boreholes or wells. These pumps are installed directly in the pumped medium, which ensures more efficient operation and allows them to cope with tasks requiring high head and performance. Submersible pumps can be used in both industrial and domestic applications, ensuring reliable and durable operation of the fluid transfer system.

TOP-4 Submersible pumps + other products

VKC Sealless Mag-Drive Vertical Pumps

The vertical centrifugal pump is designed to submerge the pump in the pumped liquid so that the electric motor remains above the liquid level. The semi-submersible chemical pump uses special construction materials and technical solutions that allow it to withstand chemical attack not only from the inside but also from the outside. We offer sealed semi-submersible vertical pumps with magnetic coupling and pumps with mechanical seal for pumping sodium hydroxide and hypochlorite, sulfuric, hydrochloric, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities, etc.

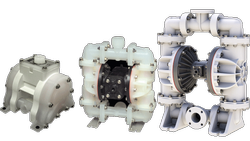

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Drum/Barrel Pumps

FINISH THOMPSON is one of the leading manufacturers of barrel pumps and a specialist in centrifugal pumps in general. The range of drum pumps includes plastic and metal models used for emptying containers, barrels, tanks, medium-duty containers and hoppers. The range of centrifugal pumps includes stainless steel pumps, ETFE-coated process pumps, plastic pumps made of polypropylene and PVDF for aggressive, difficult chemicals.

Submersible pumps: features and applications

Advantages of submersible pumps

Submersible pumps are an effective solution for pumping liquids from deep sources, such as wells or wells. Installed directly in the pumped medium, they provide more efficient operation and are able to cope with tasks requiring high pressure and productivity.

Applications in industry and everyday life

Industrial submersible pumps are widely used in industry to pump liquids over long distances and high heights. They are also used in cooling, water supply and drainage systems at enterprises in various industries. In everyday life, pumps can be used to fill reservoirs, irrigate the garden, and also to supply water from a well or borehole to the house.

Choosing a submersible pump

When choosing a submersible pump, it is important to consider such parameters as the depth of the well or borehole, the diameter of the water source, the required pressure and pump performance, as well as the characteristics of the pumped liquid. Industrial pumps have a larger diameter and power than household models, which provides them with higher performance.

Technical characteristics

Pumps can be single- or multi-stage, with different types of impellers and housing materials. They can be made of stainless steel, cast iron or plastic depending on the requirements for chemical resistance and durability. It is also important to pay attention to the engine power, the type of control system and protection against overloads and short circuits.

Maintenance and operation

To ensure a long service life of submersible pumps, it is necessary to regularly carry out their maintenance and cleaning from deposits and dirt. It is also important to monitor the condition of seals and lubricants, and if necessary, replace them. When operating the pump, safety rules and the installation and operation manual should be followed to avoid breakdowns and emergencies.

Conclusion

Submersible pumps are a reliable and effective solution for pumping liquids from deep sources in both industrial and domestic environments. The correct choice of pump, taking into account the specifics of the task and operating conditions, will ensure the efficient operation of the pumping system and the durability of the equipment.