Non-metal pumps

Non-metallic pumps are specialised devices made from materials that do not contain metals. These pumps offer a number of advantages, such as resistance to corrosion, chemicals and aggressive environments, making them an ideal choice for pumping liquids that require special cleanliness or safety, such as in the food, pharmaceutical or chemical industries. Non-metallic pumps also offer a high level of hygiene and can be effectively used in situations where contact with metal elements is undesirable or prohibited, such as the production and processing of specialised materials or medical devices.

TOP-5 Non-metal + other products

VKC Sealless Mag-Drive Vertical Pumps

The vertical centrifugal pump is designed to submerge the pump in the pumped liquid so that the electric motor remains above the liquid level. The semi-submersible chemical pump uses special construction materials and technical solutions that allow it to withstand chemical attack not only from the inside but also from the outside. We offer sealed semi-submersible vertical pumps with magnetic coupling and pumps with mechanical seal for pumping sodium hydroxide and hypochlorite, sulfuric, hydrochloric, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities, etc.

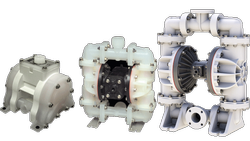

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

Non-metallic pumps: reliable and efficient solutions for industry

Non-metallic pumps are an important element of industrial processes where reliable and safe pumping of various liquids is required. They are highly resistant to corrosion and aggressive environments, which makes them an ideal choice for a wide range of industries, including chemical, food, pharmaceutical and other industries.

Advantages of industrial non-metallic pumps

Industrial non-metallic pumps have a number of advantages. Firstly, their construction from non-metallic materials such as plastic, polymers or ceramics makes them resistant to chemical attack and corrosion, which ensures a long service life. Secondly, they are usually light and compact, which simplifies their installation and maintenance. In addition, non-metallic pumps have high efficiency and performance, which allows you to save energy and resources during operation.

Choosing the optimal non-metallic pump

When choosing a non-metallic pump, several key factors must be taken into account. It is important to evaluate the type of liquid being pumped, its temperature regime, chemical aggressiveness and characteristics of the working environment in order to select a pump with the appropriate design and materials. It is also worth paying attention to the required performance, pressure and lift height to ensure optimal pump operation in specific operating conditions. The company offers a wide range of industrial non-metallic pumps of various types and models, guaranteeing high quality and reliability in every case.