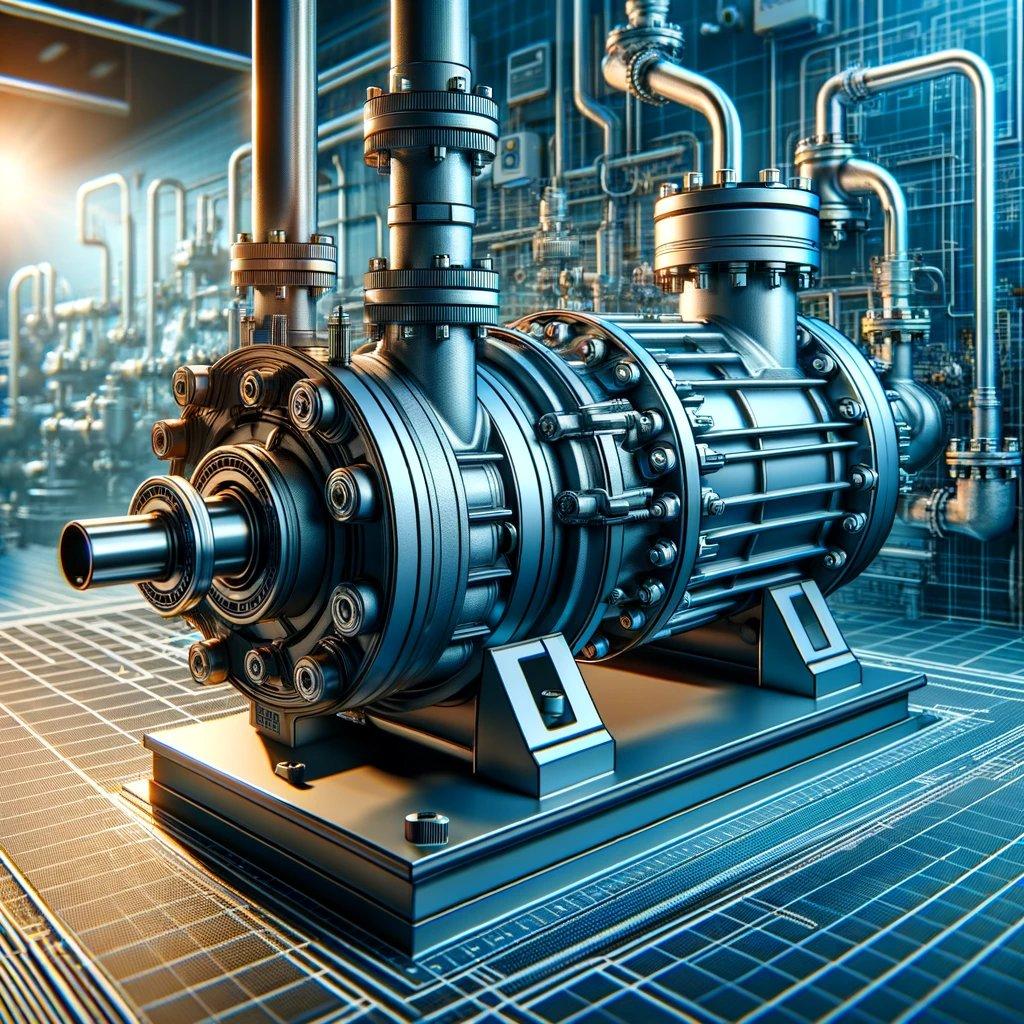

Magnetic drive pumps

Magnetic drive pumps are innovative devices that use a magnetic field to transfer mechanical energy from the motor to the pump. They differ from traditional pumps because they do not require mechanical seals between the motor and pump, making them more reliable and efficient. This type of pump is typically used in applications where a high degree of tightness and leakage prevention is required, such as in the chemical industry, water treatment, medical facilities and other industries. Due to their reliability and durability, magnetic drive pumps are becoming increasingly popular in various industrial sectors where safety and efficiency are crucial.

TOP-3 Magnetic drive pumps + other products

VKC Sealless Mag-Drive Vertical Pumps

The vertical centrifugal pump is designed to submerge the pump in the pumped liquid so that the electric motor remains above the liquid level. The semi-submersible chemical pump uses special construction materials and technical solutions that allow it to withstand chemical attack not only from the inside but also from the outside. We offer sealed semi-submersible vertical pumps with magnetic coupling and pumps with mechanical seal for pumping sodium hydroxide and hypochlorite, sulfuric, hydrochloric, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities, etc.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

Magnetic Drive Pumps

Magnetic Drive Pumps – are advanced devices that offer unique advantages over traditional pumps. Their feature is the use of a magnetic field to transfer mechanical energy from the motor to the pump, which eliminates the need for mechanical seals between the motor and the pump.

Advantages of Industrial Magnetic Drive Pumps

Industrial magnetic drive pumps offer a number of advantages:

1. Reliability and durability

Due to the absence of mechanical seals, magnetic disc pumps have higher reliability and durability. They are less prone to wear and failure, which reduces the risk of downtime and reduces maintenance costs.

2. Efficiency

Magnetic pumps provide high efficiency due to minimal energy loss. They effectively overcome hydraulic resistance and are able to provide a stable and uniform fluid flow.

3. Tightness

The use of a magnetic field eliminates problems with seals and prevents fluid leakage from the pump. This is especially important in industrial environments, where tightness plays a crucial role for the safety and efficiency of processes.

4. Versatility of application

Mag-drive pumps can be used in various industries, including chemical production, oil and gas industry, food and pharmaceutical industry, as well as water purification and wastewater treatment.

Choosing a mag-drive pump

When choosing an industrial mag-drive pump, it is important to pay attention to the following criteria:

1. Performance

Make sure that the selected pump provides the required performance and is able to operate in the conditions of your production.

2. Materials and Construction

Investigate the materials used in the pump’s construction and make sure they are resistant to the chemical effects of the working environment.

3. Dimensions and installation

Pay attention to the dimensions of the pump and its dimensions to make sure it is suitable for your equipment and installation conditions.

4. Manufacturer reliability

Purchase the pump from a reliable manufacturer with a good reputation