Pumps for Cereals

Grain pumps are specialized equipment designed for efficient pumping of grain and grain products in industrial conditions. They have a number of advantages that make them an indispensable tool in agriculture and grain production. Industrial grain pumps are characterized by high productivity, reliability and durability. They are able to provide fast and efficient pumping of large volumes of grain, which is especially important during harvest periods. In addition, they ensure accurate and uniform supply of grain products, which allows optimizing production processes and reducing product losses. Grain pumps are also characterized by ease of maintenance and operation, which makes them a convenient and reliable solution for agricultural enterprises and grain processing plants.

TOP-5 Pumps for cereals + other products

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Sandpiper plastic series

The SANDPIPER Non-Metallic AODD Pumps for standard applications are one of the most popular diaphragm pump series. The pumps are available in a wide range of sizes (1/4'' - 3''), casing materials and elastomers. The pumps are most commonly used in production areas where aggressive and explosive liquids need to be pumped. Due to their light weight, these pumps are used in portable versions for pumping liquids from drums.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

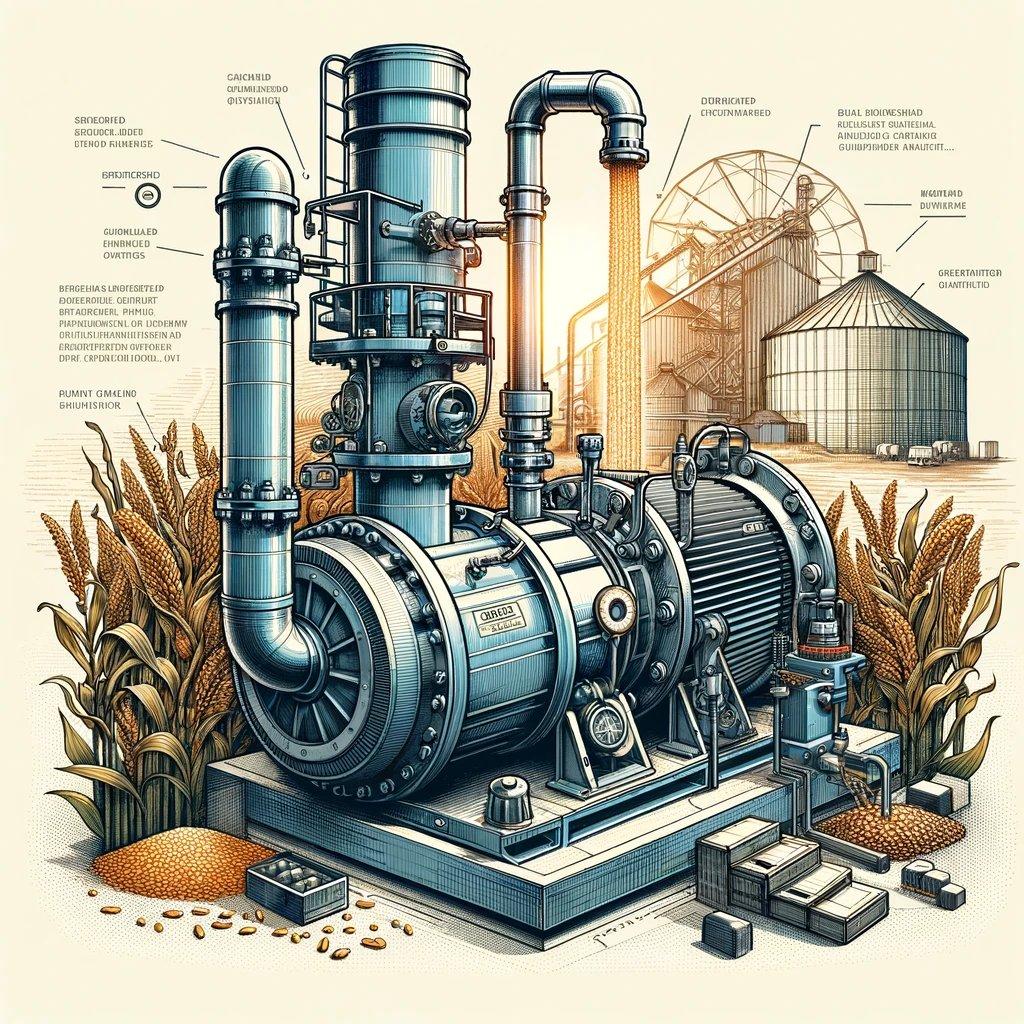

Grain Pumps: Importance in Agriculture

Advantages of Industrial Grain Pumps

Grain pumps are an integral part of modern agriculture, ensuring efficient pumping and transportation of grain products. Here are the main advantages to consider when choosing a grain pump:

- High performance: Industrial grain pumps are able to provide fast and efficient pumping of large volumes of grain, which is especially important during harvest periods.

- Reliability of operation: They are made of quality materials and have a robust design, which ensures reliable and uninterrupted operation in agricultural conditions.

- Durability: Good grain pumps have a long service life, which allows you to save on maintenance costs and equipment replacement.

- Accuracy and uniformity of feed: They ensure accurate and uniform feed of grain products, which helps reduce product losses and optimize production processes.

- Easy to maintain: The pumps are easy to maintain and repair, making them a convenient and cost-effective solution for agricultural businesses.

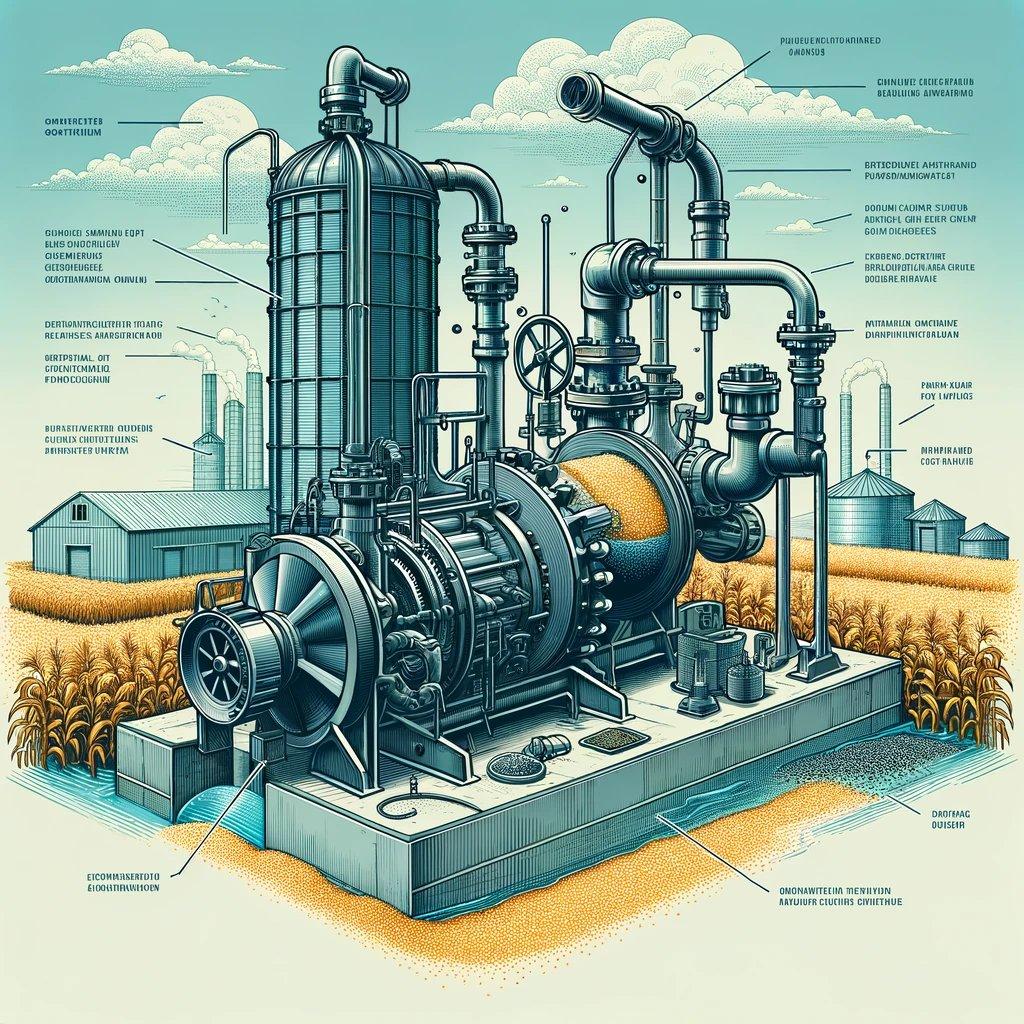

Features of choosing a pump for grain crops

When choosing a pump for grain crops, a number of key factors should be considered:

- Productivity and pressure: determine the required volume of grain pumping and the required pressure to work with the selected type of crops.

- Compatibility with different types of grain: make sure that the selected pump is suitable for pumping different types of grain crops.

- Reliability and strength of construction: choose pumps from proven manufacturers with a good reputation to be confident in the quality and durability of the equipment.

Applications of grain pumps

The most common applications of grain pumps are:

- Harvesting: for pumping and transporting grain from the field to a warehouse or granary.

- Grain processing: for pumping grain to grain processing plants for further processing and packaging.

- Agricultural production: for feeding grain to feed mills or feed mixing plants.

Conclusion

Grain pumps are an important element in agriculture, ensuring the efficient pumping and transportation of grain products. When choosing a pump, it is important to consider its performance, reliability and compatibility with the types of grain crops that will be pumped. This will help optimize production processes and reduce operating costs for grain storage and processing.