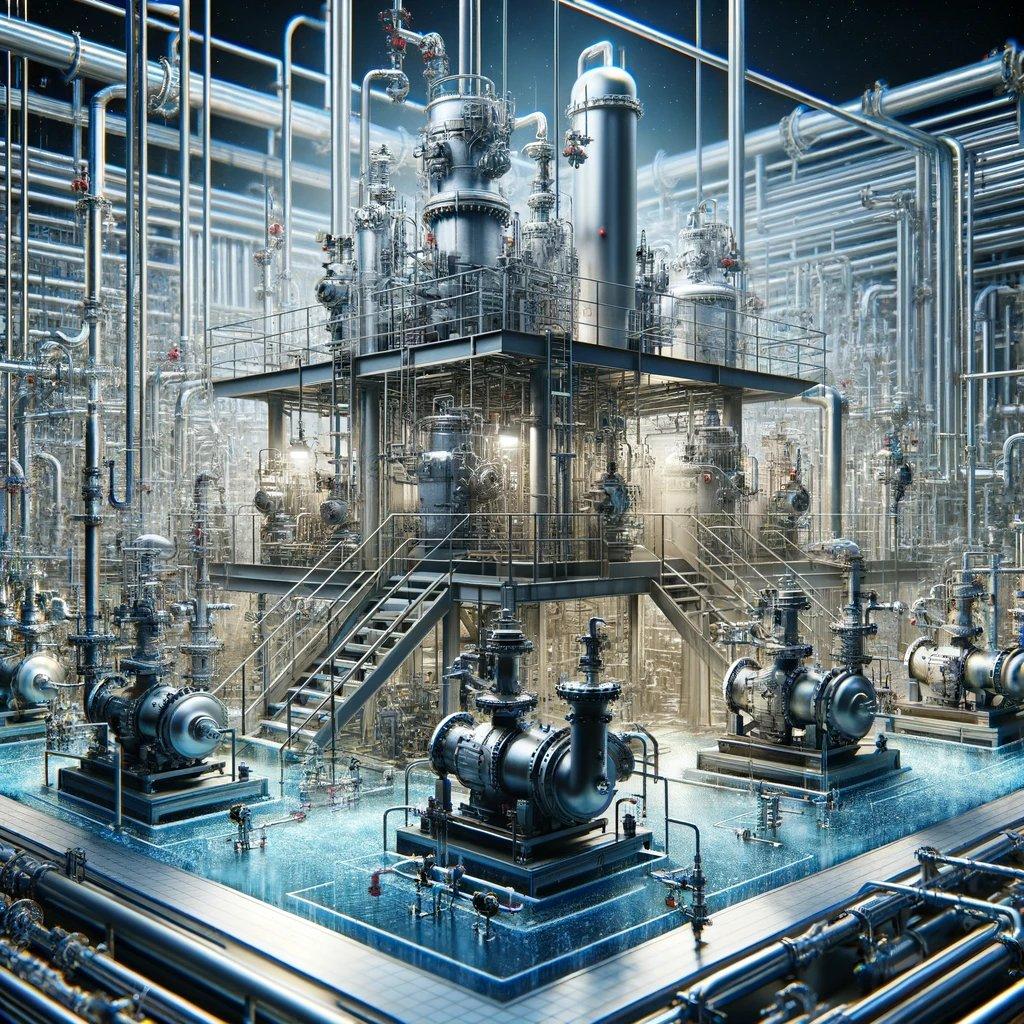

Pumps for Process condensate

Condensate process pumps are specialized devices used in various process applications to pump condensate generated in heating, air conditioning, steam generation and other industrial and commercial installations. These pumps ensure efficient system operation by moving condensate from low-lying collection points to a treatment or disposal location. They have the performance, reliability and durability to ensure uninterrupted operation of the condensate system while maintaining a high level of efficiency and cost-effectiveness.

TOP-8 Pumps for process condensate + other products

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Two-stage liquid ring vacuum pumps of the AVD series

Two-stage vacuum pumps of the AVD-AVDL series are capable of creating a maximum residual pressure of up to 33 mbar. They are in demand in cases where it is necessary to pump out various moisture in the form of steam or liquids in sufficiently large quantities. The reliability of the products is beyond doubt, they are easy to maintain, and they can be used to pump out any gas or vapour. Materials used for manufacturing range from high-quality, particularly resistant cast iron to stainless steel of the highest grades, for example, AISI 316.

Oil rotary vane vacuum pumps AVPL

The AVPL oil rotary lobe pumps are extremely compact thanks to their integrated motor and transmission, making them the ideal choice for compact installations. They are equipped with extremely robust blades that ensure a long service life. Specially designed oil filters ensure excellent oil separation, removing even the smallest oil droplets from the exhaust air.

Side Channel Blowers

Blowers are an excellent choice for many automated projects where the application requires large volumes of clean, dry air at low pressure and vacuum. We strive to provide a solution that allows for easy installation, yet provides low operating noise and energy savings in a small, lightweight design.

Vacuum Systems

If the operating conditions go beyond the potential performance provided by a liquid ring pump alone, ASCO Pompe can provide hybrid units, such as a combination of mechanical booster pumps or steam ejectors, to work in conjunction with liquid ring pumps. Both boosters and/or ejectors can be combined in series and in parallel to increase the compression ratio when a deeper vacuum is required. Hybrid systems are often a good option when the temperature of the cooling medium does not match the pump's performance. ASCO Vacuum systems are reliable and easy to operate.

Plate heat exchangers - sanitary version

Sanitary applications place unique demands on solids handling, product integrity, thorough cleaning, high efficiency and minimal downtime. With more than 60 different plate sizes to choose from, as well as technologies such as Energy-saver, Energy-saver+, Duraflow and Easyflow, APV ensures that your process requirements are met with the best possible solution. Solutions that minimise energy consumption by increasing heat transfer efficiency. Solutions that reduce plate fouling and provide easy equipment maintenance - all to minimise downtime and keep your process running smoothly.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

Condensate Process Pumps: Efficiency and Reliability

Condensate Process Pumps: Efficiency and Reliability

The Role of Pumps in Condensation

In industrial plants, power plants and other technical systems where condensate treatment and disposal are required, it is necessary to use special condensate process pumps. These pumps play an important role in pumping condensate from various system nodes, ensuring its effective removal or reuse.

Characteristics of industrial pumps

Industrial condensate process pumps are characterized by high performance, reliability and durability. They are designed to operate under high load and frequent use conditions, ensuring stable and uninterrupted operation of the condensation system. In addition, such pumps usually have special protective functions that prevent overload and emergency situations.

Applications of pumps in various industries

Condensate process pumps are widely used in the power industry, oil and gas industry, chemical industry, food industry and other industries where condensate is formed in the production process. They can be installed both in large power units and factories, and in small production facilities where condensate treatment is required.

Choosing a pump for specific tasks

When choosing a pump for a condensate process, a number of factors must be taken into account, including the volume and nature of the condensate, performance and pressure requirements, and operating conditions. It is important to choose a pump that meets specific needs and will ensure the efficient operation of the condensation system over a long period of time.