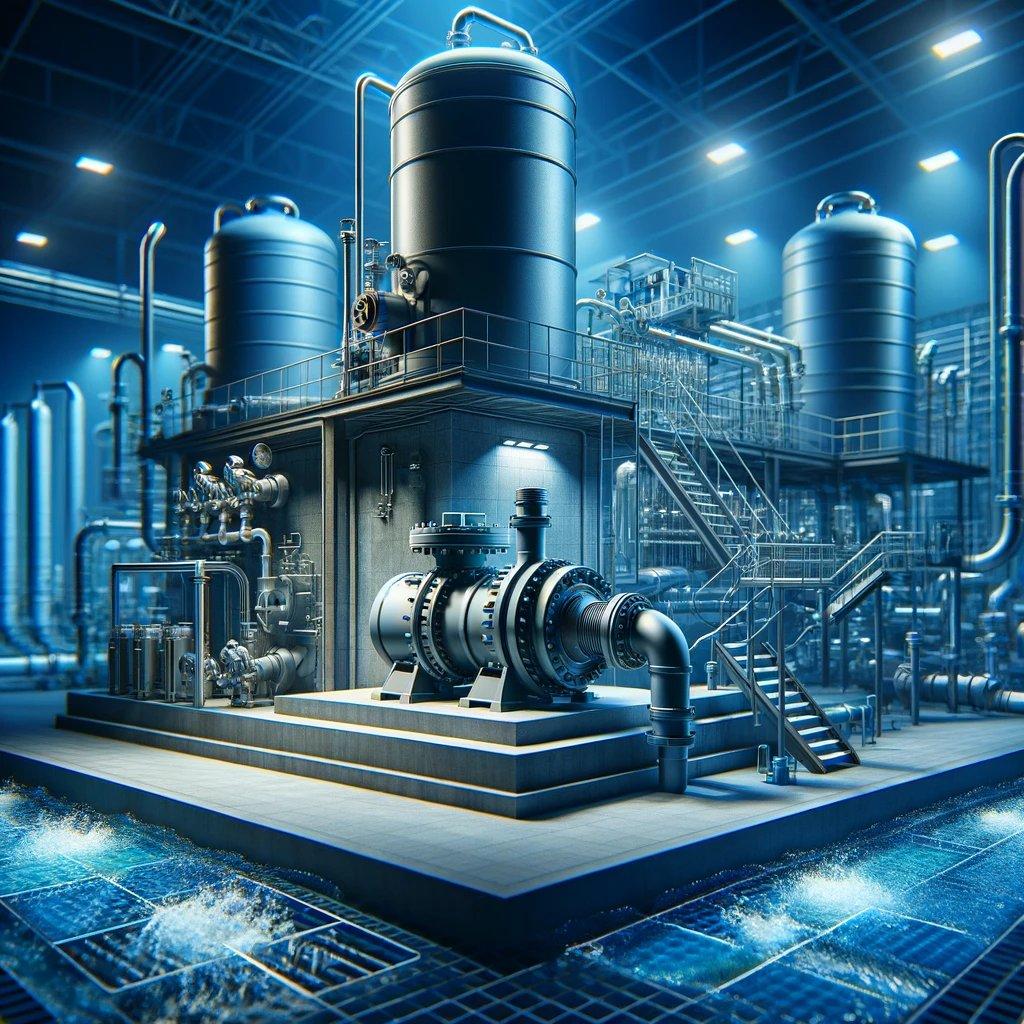

Pumps for Drinking water

Drinking water pumps are essential equipment needed to ensure continued access to clean and safe drinking water. They are used to pump water from sources such as boreholes, rivers or reservoirs to water treatment, distribution and supply systems for communities, businesses and households. Drinking water pumps have special characteristics such as high performance, reliability and efficiency, and meet strict drinking water quality and safety standards. They can be installed at open water sources, as well as in special wells or water intake facilities, and play an important role in providing a vital resource for people and businesses. When choosing a drinking water pump, it is important to consider the operating conditions, water supply needs and water quality requirements to ensure reliable and safe operation of the water supply system.

TOP-6 Pumps for drinking water + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Dellmeco plastic series

DELLMECO air-operated diaphragm pumps (AODD) are suitable for a wide range of applications. They have high abrasion resistance and can withstand aggressive chemicals, including acids, oils, solvents, paints, sludge and even media containing solid particles, such as in wastewater. These pumps can also be used for pumping powders.

All pumps are self-priming and their performance and pressure can be easily controlled. This pump is a positive displacement pump that pumps liquids by the movement of diaphragms driven by compressed air. The casing in contact with the liquid is made of polyethylene (PE), polyethylene conductive, polytetrafluoroethylene (PTFE), polytetrafluoroethylene conductive.

Valisi metallic series VC

The modern metal diaphragm pump of VC series features a unique, non-jamming air valve that is simple, robust and reliable, and does not require a separate or mechanically operated pilot valve. The bolted design ensures leak-free pumping of liquids. The pneumatic diaphragm pumps are designed and manufactured to meet the needs of both OEMs and end users. The main characteristics of these pumps are competitive prices, few parts, simple design and maintenance, and high quality. Stainless steel pumps are FDA approved. Aluminium pumps with PTFE diaphragms are explosion-proof and ATEX certified.

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

Valves and control units

Valves are the most important components of every plant. APV offers a wide range of sanitary valves, including butterfly, single-seat and double-seat valves. Additional special valves are also available, such as control, check, constant pressure and integrated safety valves. APV valves are designed to meet the ever-increasing demands for: free product flow, flow control, safe separation of liquids, and perfect cleaning.

Drinking water pumps: ensuring a reliable water supply

The benefits of using drinking water pumps

Drinking water pumps play an important role in ensuring a reliable and safe water supply. They are designed to pump water from sources such as boreholes, rivers or reservoirs to a water treatment and distribution system. The use of drinking water pumps allows to provide access to clean and safe drinking water in both urban and rural areas, where it is especially important for public health.

Characteristics of industrial drinking water pumps

Industrial drinking water pumps have a number of features that make them an ideal choice for a variety of water supply systems. They usually have high performance, reliability and durability, which ensures stable operation of the water supply system. In addition, they are often equipped with special filters and purification systems that help maintain high quality drinking water.

Application of drinking water pumps in various fields

Drinking water pumps are widely used not only in providing water supply to residential buildings, but also in industry, agriculture, medicine and other industries. They are used to pump water in manufacturing plants, irrigate farmland, provide water supply to hospitals and clinics, and support the operation of the fire extinguishing system.

Choosing a drinking water pump

When choosing a drinking water pump, a number of factors must be considered, including the volume of water to be pumped, the required pressure, the characteristics of the working environment and the operating conditions. It is important to choose a pump that best meets the needs of your water supply system to ensure reliable and efficient operation.

For industrial drinking water applications, you’ll need pumps that ensure high efficiency, durability, and compliance with drinking water standards.

1. Centrifugal Pumps

- Ideal for large-scale water distribution.

- High flow rates with moderate pressure.

- Used in municipal water supply systems.

2. Vertical Turbine Pumps

- Suitable for deep wells and water treatment plants.

- Efficient for high-capacity water movement.

3. Submersible Pumps

- Fully submerged, reducing noise and energy loss.

4. Booster Pumps

- Increases pressure in water distribution networks.

- Used in bottling plants, food & beverage industries.

5. Diaphragm Pumps

- Used for precise metering in water treatment processes.

- Handles additives and chemical dosing.

6. Positive Displacement Pumps

- Ideal for consistent water flow at varying pressures.

- Used in specialized industrial applications.