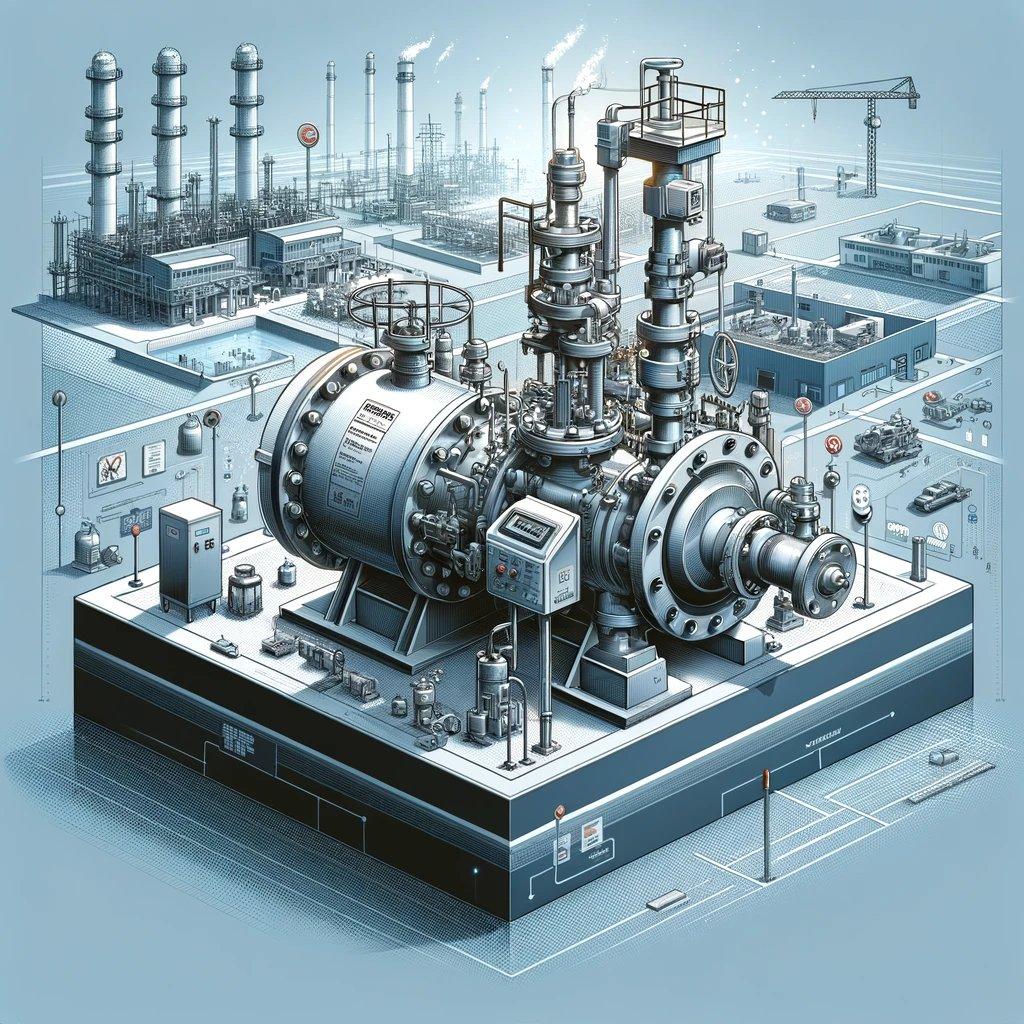

Pumps for LPG

Liquefied petroleum gas (LPG) pumps are specialized equipment designed for pumping and transporting liquefied petroleum gas. They play an important role in the oil and gas industry, ensuring reliable and efficient operation of gas liquefaction, storage and transportation systems. LPG pumps are distinguished by their special design and materials resistant to low temperatures and aggressive chemical environments that accompany the gas liquefaction process. They provide high pumping performance and efficiency, as well as reliable operation in operating conditions on offshore platforms, in hard-to-reach places and at gas production and processing facilities. LPG pumps are widely used in the gas industry to ensure continuous and safe operation of liquefied petroleum gas transportation and distribution systems.

TOP-5 Pumps for lpg + other products

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Heavy-duty gear pumps

Heavy-duty gear pumps solve the toughest applications and ensure maximum flow rates when emptying large tanks. The foot-mounted design of the pump allows the use of various types of mechanical seals without changing the design of the pump itself (Universal Seal series). A large bearing cup located at the rear of the pump allows the installation of any seal, from a conventional stuffing box to a double mechanical seal.

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

Liquefied Petroleum Gas (LPG) Pumps: Importance and Features

Industrial Liquefied Petroleum Gas (LPG) Pumps

Liquefied Petroleum Gas (LPG) pumps play a key role in the oil and gas industry, ensuring continuous and safe pumping of gas at various stages of its production and transportation. Here is what is important to know for the buyer of an LPG pump:

- Specialized design: LPG pumps have a special design and materials resistant to low temperatures and aggressive chemical environments, which makes them reliable and durable in operating conditions on offshore platforms, in hard-to-reach places and at gas production and processing facilities.

- High performance: Industrial LPG pumps provide high gas pumping performance, which allows you to effectively manage the flow and ensure the continuity of production processes.

- Operational safety: LPG pumps are equipped with control and safety systems that minimize the risk of emergencies and ensure the safety of pumping and storing liquefied petroleum gas.

- Efficiency and savings: The use of industrial LPG pumps allows you to optimize production processes, reduce operating costs and increase the overall efficiency of gas transportation and distribution systems.

Choosing a Liquefied Petroleum Gas (LPG) Pump

When choosing a Liquefied Petroleum Gas (LPG) pump, it is important to consider the following factors:

- Required Capacity: Determine the required gas pumping volume depending on the scale of production tasks and needs.

- Gas Compatibility: Make sure that the selected pump meets the characteristics of liquefied petroleum gas and is able to provide efficient and safe operation with it.

- Reliability and Durability: Buy pumps from proven manufacturers with a good reputation to be confident in the quality and durability of the equipment.

Conclusion

Liquefied Petroleum Gas (LPG) pumps play an important role in the oil and gas industry, ensuring reliable and efficient pumping of gas at various stages of its production and transportation. When choosing an LPG pump, you should consider its specialized design, high performance, operational safety, and compatibility with gas characteristics, which will help ensure the efficiency and reliability of LPG transportation and distribution systems.