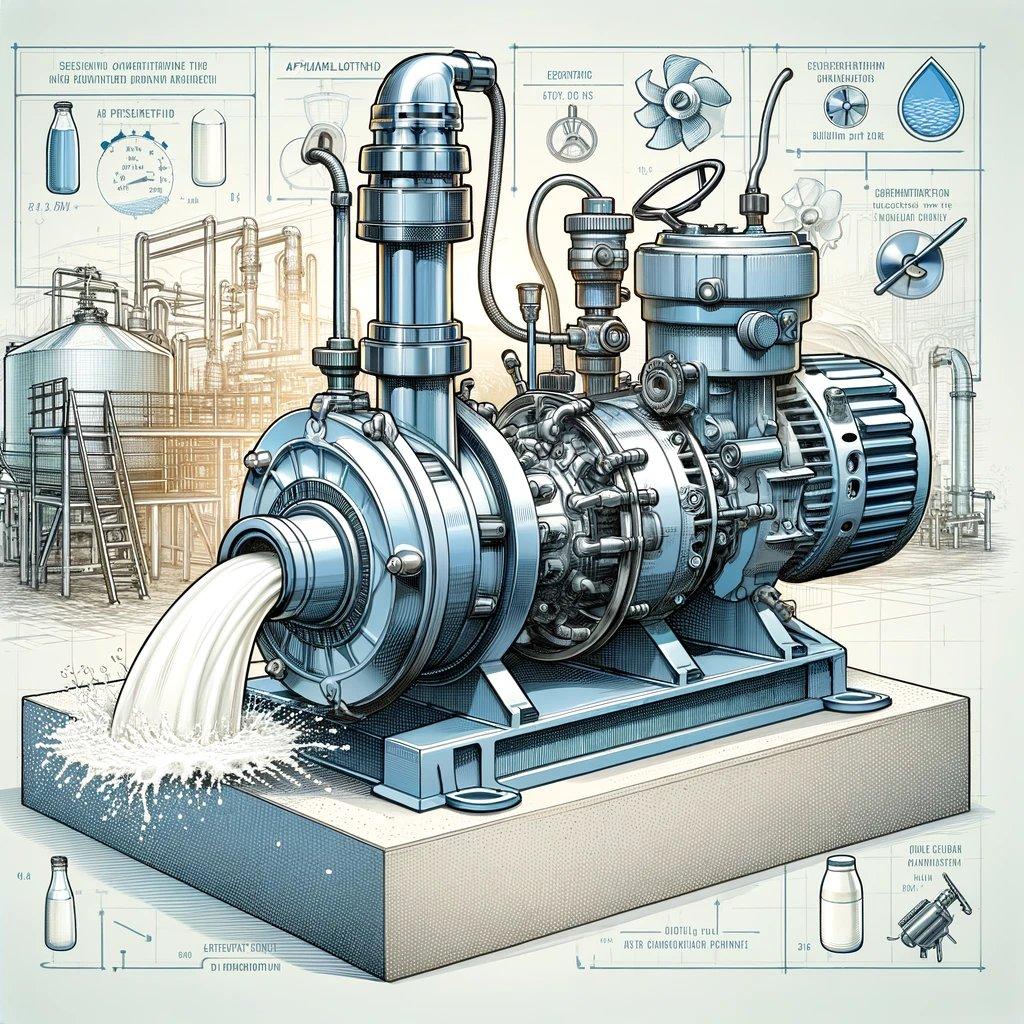

Pumps for Milk

Milk pumps are specialized devices used in agriculture and the dairy industry to transfer milk from the milking area to the storage or processing area. These pumps have special features that ensure gentle handling of the milk, prevent contamination, and maintain its quality. Industrial milk pumps can be made from materials that are safe for the product, ensuring compliance with food industry hygiene and safety standards. They can also have special design features, such as sanitary compounds and surfaces that are easy to clean and disinfect, to minimize the risk of contamination. Milk pumps come in a variety of types, including centrifugal, vacuum, and piston, each of which can be configured to suit specific needs and the volume of milk being pumped. They play a key role in ensuring the efficient collection and processing of milk, making them essential equipment for dairy farms and dairy processing plants.

TOP-16 Pumps for milk + other products

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Flexible impeller pumps

The MENC-INOX industrial pumps are pumps with a flexible stainless steel impeller. The impeller deforms inside the stainless steel casing to provide fast suction of up to 5 m and constant and accurate liquid transfer. In addition, the low speed makes this pump suitable for pumping liquids and media containing solids that require careful handling. Due to the low speed, pumping is carried out without harmful foaming of the emulsion, the so-called "shear effect".

Hose pumps N series

Peristaltic pumps of the N series (roller design) are self-priming peristaltic pumps with a seal-free design. The liquids are transported inside the hose and do not come into contact with any metal parts of the pump.

The pumps are characterised by extremely smooth pumping of the product, thus preventing the formation of emulsions or turbulence. All pumps can be supplied in monoblock versions connected to gearboxes, regulators, electric, diesel, pneumatic or hydraulic motors.

Oil rotary vane vacuum pumps AVPL

The AVPL oil rotary lobe pumps are extremely compact thanks to their integrated motor and transmission, making them the ideal choice for compact installations. They are equipped with extremely robust blades that ensure a long service life. Specially designed oil filters ensure excellent oil separation, removing even the smallest oil droplets from the exhaust air.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Flex-Mix™ ТРМ

Flex-Mix ™ ТРМ - is a mixer used for mixing powders and liquids in the production of dairy products, sugar syrups, brines, etc.

Flex-Mix™ TРХ

The TPX static inline mixer is used to continuously mix various combinations of liquids, gases and particles. The mixer is also well suited to ensure a uniform mixing temperature, e.g. by direct steam supply. The static mixer can be used for pre-mixing and post-mixing. It can be used for mixing dairy products such as cream and milk to normalization, starter and milk, fat and recombined milk.

Hygienic Progressive Cavity Pump

The hygienic screw pumps are specially designed for use in the food, cosmetics and beverage industries. The pumps have a simple design, which greatly simplifies their cleaning. All metal parts in contact with the pumped product are made of SS304 / SS316 stainless steel. For the transport of materials with high viscosity, pumps with a wide discharge hopper are designed.

Sanitary plate heat exchangers

Plate heat exchangers for hygienic applications are designed for efficient heating and cooling of mechanically sensitive products in processes with high hygiene requirements. Such heat exchangers consist of a set of stainless steel plates combined into a single structure. This design can consist of several plate packs that make up separate sections in which different processing stages are carried out, such as primary heating, main heating and cooling. The heating medium is hot water, and the cooling medium is cold water, ice water or propylene glycol, depending on the required outlet temperature of the product.

Valves and control units

Valves are the most important components of every plant. APV offers a wide range of sanitary valves, including butterfly, single-seat and double-seat valves. Additional special valves are also available, such as control, check, constant pressure and integrated safety valves. APV valves are designed to meet the ever-increasing demands for: free product flow, flow control, safe separation of liquids, and perfect cleaning.

High-pressure homogeniser Rannie/Gaulin

The equipment required for a homogeniser includes all components that can grind liquid particles, resulting in a homogeneous and stable product emulsion. Industrial and laboratory high-pressure homogenisers are direct-acting piston pumps equipped with a pressing unit and a homogenising valve, which can be used in various industries and improve product quality and stability.

What should a homogeniser be used for? Homogenisers are widely used in the dairy, food, healthcare, cosmetic, chemical, biotechnology and pharmaceutical industries. They can provide significant added value, improved product quality and competitive advantage. Systems can be designed and configured to offer specific product characteristics, including:

- Significantly improved product palatability

- Particle size control for more homogeneous, finer emulsions

- Reduced amount of emulsifiers and stabilisers required

- Improved binding to water

- Improved colour properties

- Homogeneous emulsions

- Creams and lotions that are easier to apply

Pumps for milk

Industrial Milk Pumps

Milk pumps are essential equipment for farms and dairies that pump and process milk. They play a key role in ensuring the efficient movement of milk from the milking point to the storage or production area where it is further processed.

Industrial milk pumps are usually made of high-quality materials, such as stainless steel, which ensures a high level of hygiene and safety in contact with food products. They also have special design features that allow them to effectively handle liquids containing solid particles, such as milk with sediment.

Characteristics of milk pumps

There are different types of milk pumps on the market, each of which has its own characteristics and advantages. Among the main characteristics that should be considered when choosing a milk pump, the following can be distinguished:

- Performance: An important parameter is the performance of the pump, that is, the amount of milk it is able to pump in a certain period of time. Choosing a pump with the right performance allows you to optimize the pumping process and increase production efficiency.

- Pressure: For the pump to work effectively, it is necessary to take into account the required pressure of the pumped liquid. Milk pumps usually provide low pressure, which avoids damage to the milk pipelines and preserves the integrity of the product.

- Hygiene: Particular attention should be paid to the hygiene of the pump and its ability to ensure the safety of the milk. Choosing a pump with smooth surfaces and no hidden areas helps prevent the accumulation of bacteria and facilitates the cleaning and disinfection process.

Choosing a milk pump

Choosing a milk pump

When choosing a milk pump, it is necessary to take into account a number of factors, including production volume, technological process features and product hygiene and safety requirements. It is also important to pay attention to the reputation of the manufacturer and the quality of the equipment offered.

Milk pumps are reliable and efficient equipment that helps ensure high quality and safety of dairy products. The right choice of pump allows you to optimize production processes and increase the efficiency of the dairy enterprise.