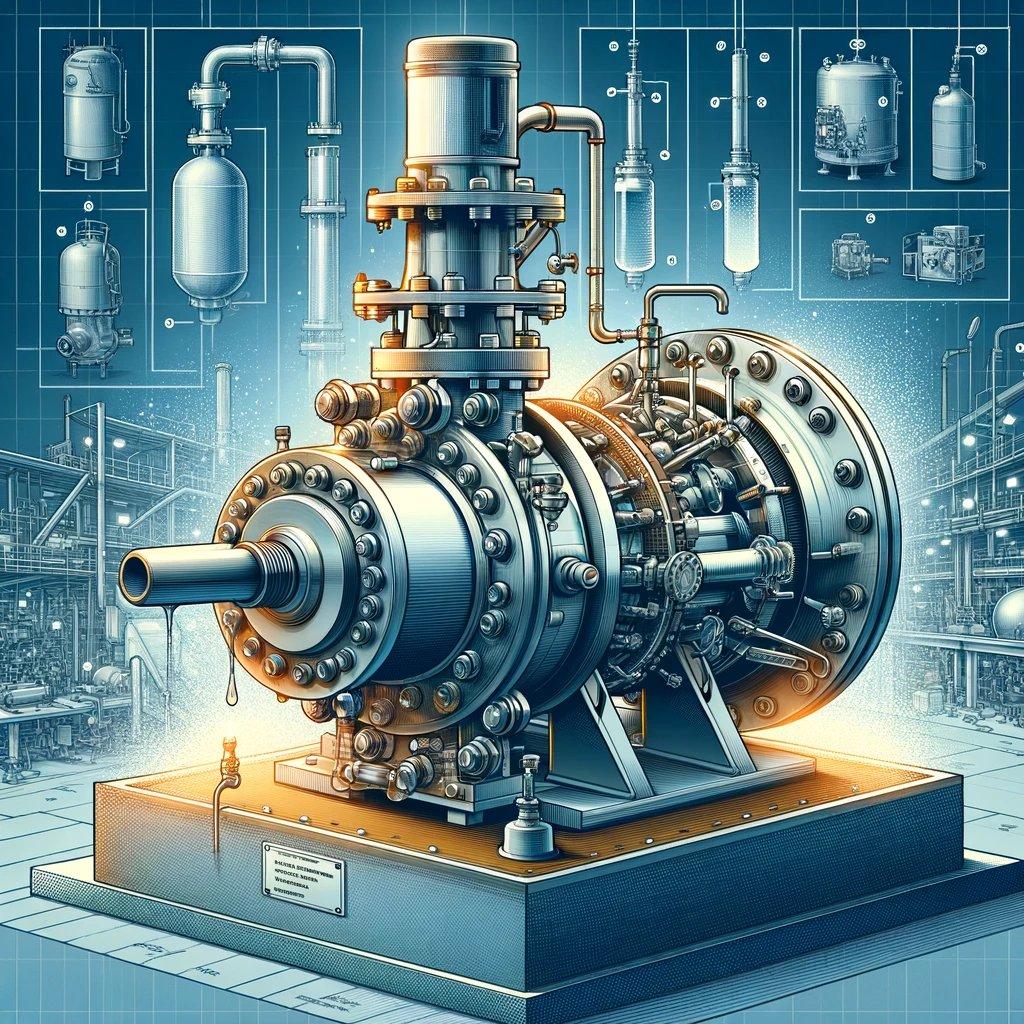

Pumps for Cryogenic liquids

Pumps for cryogenic liquids are specialised devices designed to pump liquids that are at extremely low temperatures close to absolute zero. Such liquids include liquefied gases such as oxygen, nitrogen, argon, hydrogen and helium, which are used in industry and research. Pumps for cryogenic liquids have to be specially designed to meet the extreme operating conditions, ensuring reliable and safe pumping at extremely low temperatures.

TOP-5 Pumps for cryogenic liquids + other products

API 674 & API 675 Injection, Transfer and Dosing Pumps

The Wanner Hydra-Cell Pro® G-Series process pumps are highly efficient and reliable for transferring corrosive, non-lubricating and abrasive liquids, injecting and spraying a wide range of fluids. The pumps are equally suitable for high and low pressure applications. The sealed design reduces maintenance and repair costs and minimises the cost of spare parts compared to other pump types. The pumps are available with SAE, ANSI or DIN flanges and IEC or NEMA motor mounts. The equipment is ATEX certified.

API 674 High Horsepower Process Pumps

Reduce energy consumption and lower maintenance costs with Wanner Hydra-Cell Pro® T & Q series, a triplex multi-diaphragm pump (three-piston) or a quintuplex (four-piston) diaphragm pump. These seal-less and packing-free pumps meet API 674 standards and are designed for heavy-duty applications for process, transfer and injection for the oil and gas industry.

API 675 Metering & Dosing Pumps

Hydra-Cell Pro® Metering Solutions pumps meet and, in most cases, exceed API 675 performance standards by providing virtually pulse-free, linear flow, as well as many other operational benefits. Taking advantage of state-of-the-art technology, Hydra-Cell Pro® P-Series metering pumps achieve superior levels of accuracy, repeatability and linearity, delivering precise, consistent flow. This revolution in metering uses the latest electronic flow control available to replace outdated, inaccurate stroke controllers.

SP Series Self-Priming Pumps

The SP series plastic centrifugal sealed chemical pumps with magnetic coupling are ideal for pumping aggressive liquids, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended solids should be no more than 1.25 mg/cubic cm. All pump components in contact with the medium are free of metal parts. Thus, no oxidation of the medium occurs in these pumps. The pumps are used even for media where contact with the atmosphere is not permitted.

DB Series Sealless Plastic Pumps

The non-self-priming plastic centrifugal hermetic chemical pumps with magnetic coupling of the DB series are one of the most popular chemical pumps in the pump segment with a capacity of up to 50 m3/h. The pumps are ideal for pumping aggressive liquids such as sodium hydroxide and hypochlorite, sulfuric acid, hydrochloric acid, nitric acid, alkalis, various corrosive mixtures, solvent, wastewater with chemical impurities. The concentration of suspended particles should not exceed 1.25 mg/cubic cm.

Pumps for cryogenic liquids

Cryogenic fluid pumps are essential equipment for a variety of industries that require handling liquids at extremely low temperatures. These pumps are specially designed to provide safe and efficient pumping of liquid cryogenic gases such as oxygen, nitrogen, hydrogen, argon and helium, which are used in a wide range of processes and applications.

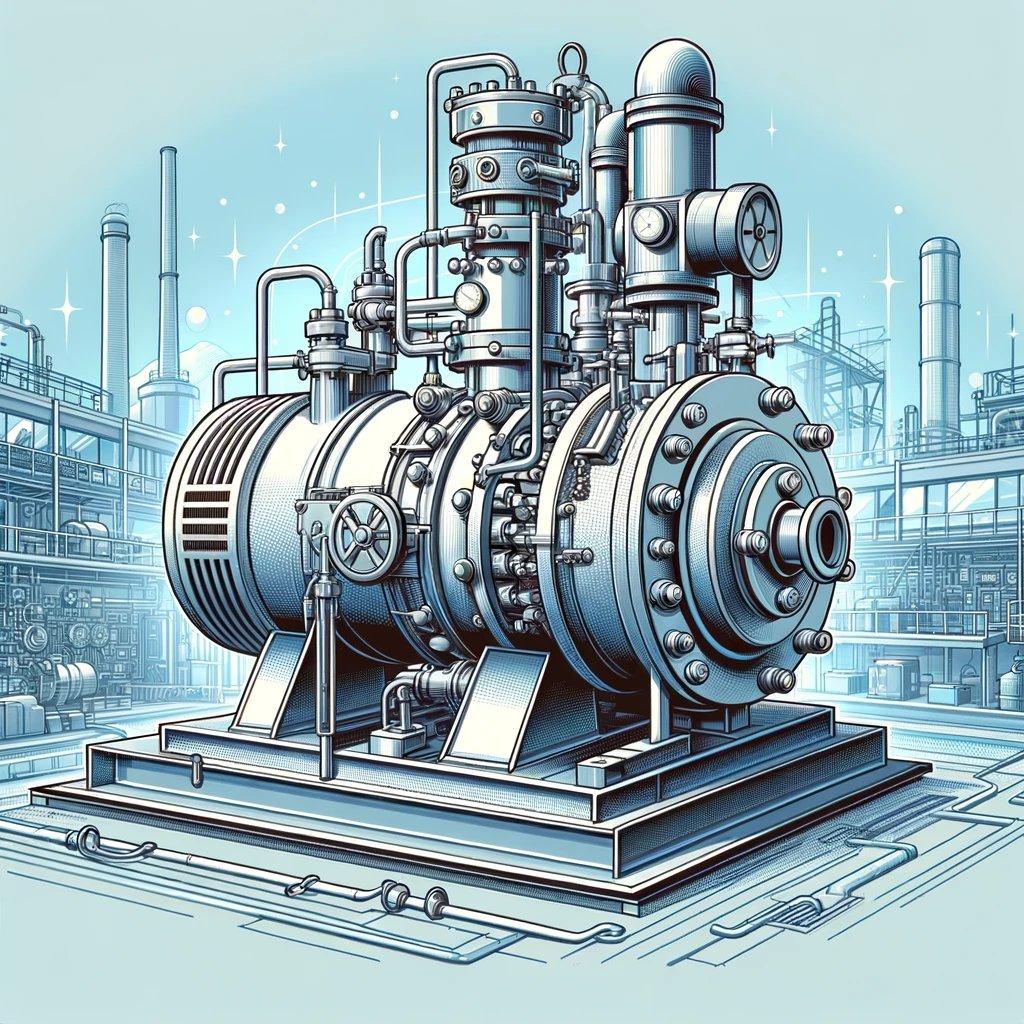

Advantages of industrial pumps for cryogenic liquids

Industrial pumps for cryogenic liquids offer a number of advantages that make them indispensable equipment for low-temperature fluid handling:

- High efficiency: the pumps are designed to operate efficiently and reliably at extremely low temperatures, ensuring high process performance.

- Safety: industrial cryogenic liquid pumps have special safety systems to prevent spillage and leakage of liquid gas, which guarantees the safety of personnel and equipment.

- Durability: made of high quality materials that can withstand low temperatures and chemical attack of cryogenic liquids, ensuring a long service life of the pump.

- Adaptability: the pumps can be adapted to different needs and operating conditions due to the variety of pump configurations and types, as well as the possibility of parameter adjustment.

Applications of pumps for cryogenic liquids

Applications of pumps for cryogenic liquids

Cryogenic fluid pumps are used in a variety of industries and research applications:

- Medicine: in medical applications to ensure the oxygen supply in oxygen concentrators and cryotherapy.

- Electronics manufacturing: to create a clean ambient gas in film deposition and coating processes.

- Steel and metal production: for nitrogen cooling during metal hardening and annealing.

- Research and scientific projects: in the laboratory to handle cryogenic liquids during physical experiments and research.

So, choosing a cryogenic liquid pump is an important decision that depends on the specific needs of your production or project. When choosing a pump, it is important to consider its technical characteristics, reliability, safety and compatibility with the specific cryogenic liquid.