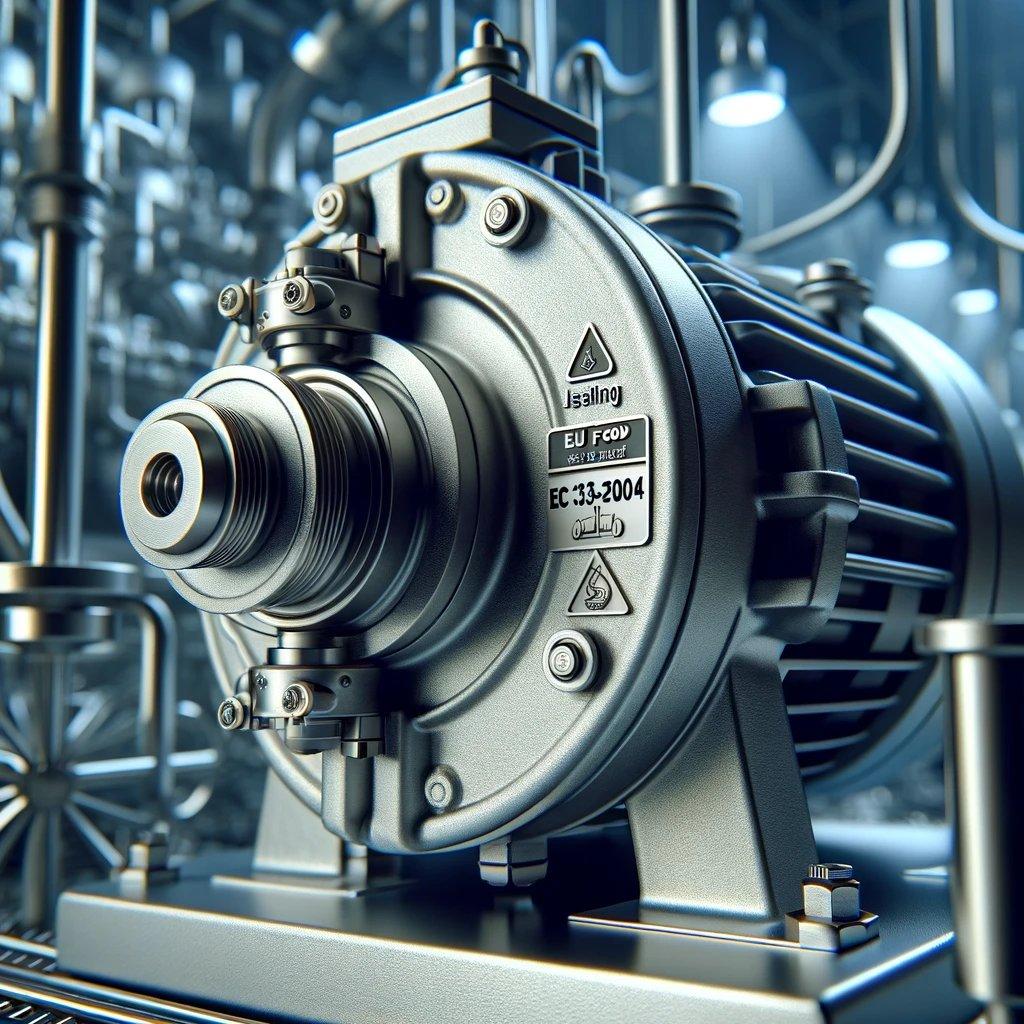

Pumps certified EU Food EC 1935/2004

EU Food EC 1935/2004 certified pump is a pumping equipment that meets the requirements and standards of the European Union for food safety as set out in regulation EC 1935/2004. This certification confirms that the pumps can be safely used in the food industry to pump liquids in contact with food and that they do not endanger the health of consumers. This makes EU Food EC 1935/2004 certified pumps the ideal choice for food manufacturers who want to meet high safety and quality standards.

TOP-2 Pumps certified EU Food EC 1935/2004 + other products

Valisi non-metallic series

Despite their simple design and operating principle, Valisi plastic diaphragm pumps are characterised by exceptional performance and reliability. They can be used to pump clean liquids with low viscosity as well as abrasive liquids with medium viscosity. In addition, these pumps can handle large particles without damaging the equipment. And thanks to the pneumatic motor, they can be used in explosive atmospheres.

Rotary lobe pumps

Rotary Lobe Pumps are reliable and efficient solutions for pumping liquids in a wide range of industries that require reliable and wear-resistant technology.

Rotary Lobe Pumps are reliable thanks to its hygiene design, capable of pumping without damaging liquid’s structure, and depending on liquid’s viscosity, Rotary Lobe Pumps have the ability of generating pressure up to 12 Bar.

EU Food EC 1935/2004 Certified Pumps

EU Food EC 1935/2004 certified pumps are high-quality pumps designed to meet strict safety and hygiene standards for contact with food. They meet the European Union requirements for materials intended for contact with food and ensure reliable and safe operation in the food industry.

Advantages of EU Food EC 1935/2004 Certified Pumps

1. Product Safety: These pumps ensure that food products are not contaminated and remain safe for consumption by complying with EC 1935/2004 standards.

2. High hygiene: Made of materials approved for contact with food, the pumps ensure a high level of hygiene during food processing.

3. Reliable operation: EU Food EC 1935/2004 certified industrial pumps ensure stable and efficient operation in food production environments.

Applications of EU Food EC 1935/2004 certified pumps

1. Beverage production: They are ideal for pumping juices, beverages and other liquids that require a high degree of hygiene.

2. Food processing: Used for pumping and processing dairy products, sauces, purees and other food ingredients.

3. Pharmaceutical Industry: Essential for handling pharmaceutical liquids and medical products where a high level of safety is required.

Choosing EU Food EC 1935/2004 certified pumps

When choosing pumps for the food industry, pay attention to their certification according to EC 1935/2004 standards, which guarantees compliance with the high safety and hygiene standards required for working with food products.