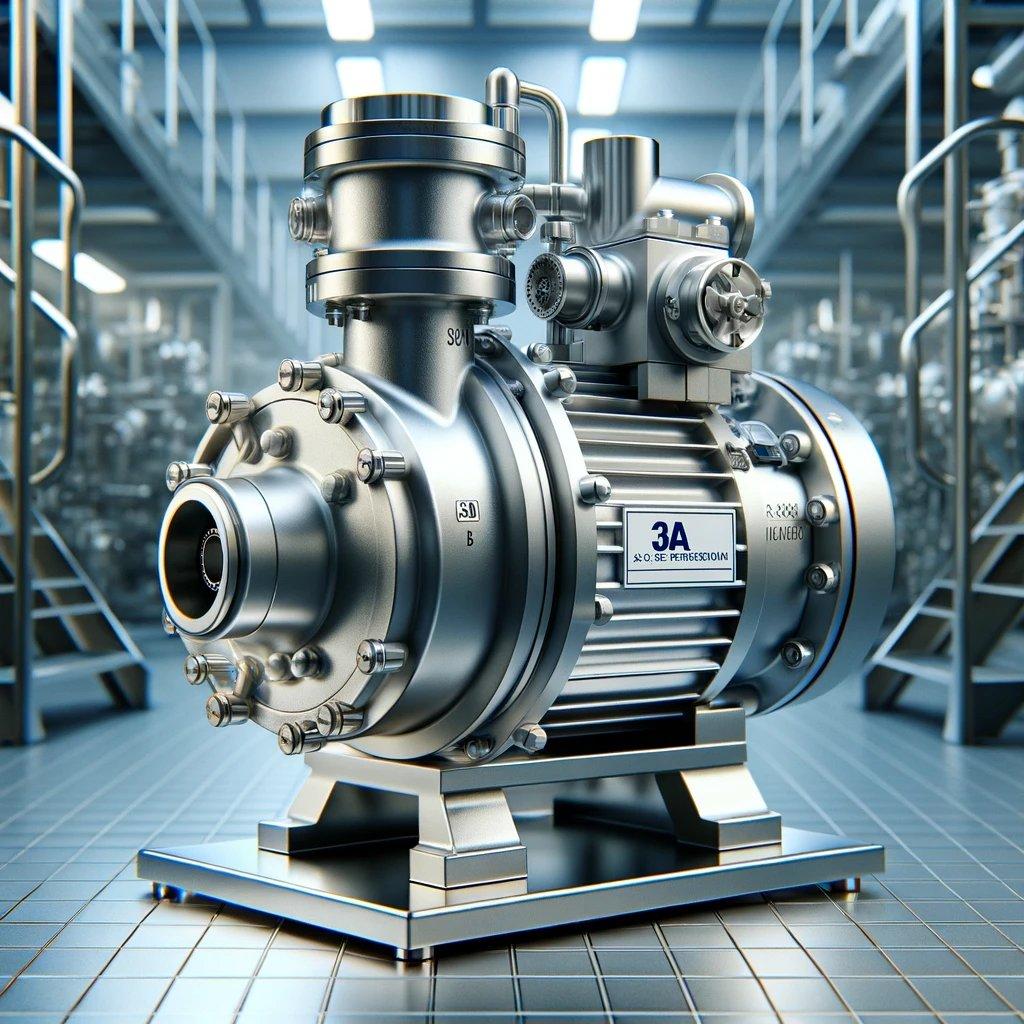

Pumps certified 3A

3-A certified pump is a pump that meets the standards and requirements set by the 3-A Sanitary Standards organisation. These standards are designed to ensure safety, hygiene and quality in food and pharmaceutical production. 3-A certified pumps have undergone rigorous inspections and testing to ensure that they can handle products without the risk of contamination or undesirable material interaction. They are widely used in the food and beverage industry, pharmaceuticals and other industries that require a high level of hygiene and safety when pumping liquids and paste-like products.

TOP-14 Pumps certified 3A + other products

Tubular heat exchanger - ParaTube

In some cases, tubular heat exchangers are used for pasteurization and sterilization of dairy products. Unlike plate heat exchangers, these heat exchangers have no contact points in the product channel and can therefore be used to handle products whose particles are limited to a certain size. The maximum particle size depends on the pipe diameter. When operating in sterilization mode, a tube heat exchanger is less likely to need to be stopped for cleaning than a plate heat exchanger. In terms of heat transfer, a tube heat exchanger is less efficient than a plate heat exchanger.

Single-seat valve MS4/MSP4

The MS4 and MSP4 aseptic single seat valve series are designed for applications in the food, beverage, dairy, pharmaceutical and chemical industries. These valves are available in shut-off, change over, and tank outlet configurations.

Flex-Mix™ Instant

Flex-Mix™ Instant is a high-performance vacuum process unit suitable for use in a variety of industrial applications. It is designed to recombine, dissolve and disperse powdered products in liquids using high shear rate vacuum mixing.

Plate heat exchangers - sanitary version

Sanitary applications place unique demands on solids handling, product integrity, thorough cleaning, high efficiency and minimal downtime. With more than 60 different plate sizes to choose from, as well as technologies such as Energy-saver, Energy-saver+, Duraflow and Easyflow, APV ensures that your process requirements are met with the best possible solution. Solutions that minimise energy consumption by increasing heat transfer efficiency. Solutions that reduce plate fouling and provide easy equipment maintenance - all to minimise downtime and keep your process running smoothly.

Centrifugal pump W +

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind. Energy-saving sanitary centrifugal pumps of the W+ series are characterized by increased reliability and a high level of hygiene. The pump series consists of 17 standard models.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

WAUKESHA lobe pumps

Waukesha lobe pumps are represented by two main series: Universal I and Universal II. They differ in operating pressure and some design features. The former operates at a pressure of 13.8 bar, and the latter at 34.5 bar. The Universal II models are equipped with a three-pin stationary seal. The pumps used in the food and pharmaceutical industries meet all hygiene and safety standards. For pharmaceutical equipment, a smooth internal surface is mandatory. For both series of pumps, all parts and structures can be rinsed.

Butterfly valve SV/SVS

The DELTA SV/SVS butterfly valves are manually or pneumatically operated shut-off valves. The valves are very robust and reliable and their compact design makes them ideal for almost all applications. The valve is very easy to install and maintain.

Single-seat valve SW4

When designing this valve, great care was taken to make it easy to handle, install and maintain.

Its hygienic design makes it ideal for use in the dairy, beverage and brewing industries as well as in the chemical and pharmaceutical industries.

Rannie Three-Piece valve housing

Modular design consisting of a three-piece valve body and individual cylinders (3 IFI 5). The three blocks around the pump valves have a very simple and user-friendly design which, together with the individual cylinders, provide very high pressures.

Rotary lobe pump R

The R-series pump is ideal for the type of application where pumps with metal rotors will not work effectively. When you need to strip clean your pump because the product will not wash out by using a normal CIP process such as meat processing, the R pump overcomes this problem by its simple robust design. The R pump design utilities a floating rotor without rotor nuts. Rotors are interchangeable and can only be fitted in one position due to a specially modified square shaft.

Rotary lobe pump DW

The DW pump series is the newest series of SPX FLOW rotary lobe pumps. No other cam pump on the market today offers such a wide range of functions in one pump. DW pump models are hygienic and meet all the requirements of industrial standards 3-A and EHEDG. All parts in contact with the product are made of AISI 316L stainless steel and the elastomers meet FDA requirements.

Flex-Mix™ ТРМ

Flex-Mix ™ ТРМ - is a mixer used for mixing powders and liquids in the production of dairy products, sugar syrups, brines, etc.

Flex-Mix™ TРХ

The TPX static inline mixer is used to continuously mix various combinations of liquids, gases and particles. The mixer is also well suited to ensure a uniform mixing temperature, e.g. by direct steam supply. The static mixer can be used for pre-mixing and post-mixing. It can be used for mixing dairy products such as cream and milk to normalization, starter and milk, fat and recombined milk.

3-A Certified Pumps

3-A Certified Pumps are high-quality pumps that meet the strict safety, hygiene and quality standards set by the 3-A Sanitary Standards organization. These pumps are a reliable solution for various industrial applications, especially in the food and pharmaceutical industries, where a high level of hygiene and safety is required when handling and pumping liquids and pasty products.

Advantages of 3-A certified pumps

- Compliance with strict safety and hygiene standards

- Guaranteed reliability and product quality

- Can be used in the food and pharmaceutical industries

- High level of hygiene when pumping products

- Efficiency and durability in operation

- Easy to maintain and adjust to specific process requirements

3-A certified industrial pumps for various industries

3-A certified pumps are widely used in various industries due to their versatility and reliability. In the food industry, they ensure safe and hygienic pumping of products, maintaining their quality and purity. In the pharmaceutical industry, 3-A certified pumps guarantee compliance with high standards of pharmaceutical production and safety when working with sensitive products.

Key features of 3-A certified pumps

- Special materials resistant to chemically aggressive environments

- Modern technologies that ensure high performance and efficiency

- The possibility of individual adjustment and configuration to specific customer requirements

- 3-A certification as a guarantee of compliance with high safety and hygiene standards

- A wide selection of pump models and types for various industrial tasks

Conclusion

Choosing 3-A certified pumps provides customers with reliability, safety and high quality when working with liquids and pasty products in various industries. These pumps are a modern and effective solution for ensuring hygienic and safe pumping of products, meeting the highest standards of production and operation.