Pumps for Replacement

Replacement pumps are essential equipment required to replace or upgrade existing pumping systems in a variety of industries. They are used to pump liquids, bulk materials or gases efficiently and ensure reliable operation of production processes. Industrial replacement pumps offer high performance, durability and efficiency, which helps to improve production performance and reduce maintenance costs. Replacement pumps can be adapted to different operating conditions and industry-specific requirements, making them a sought-after solution for modernising industrial processes.

TOP-3 Pumps for replacement + other products

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

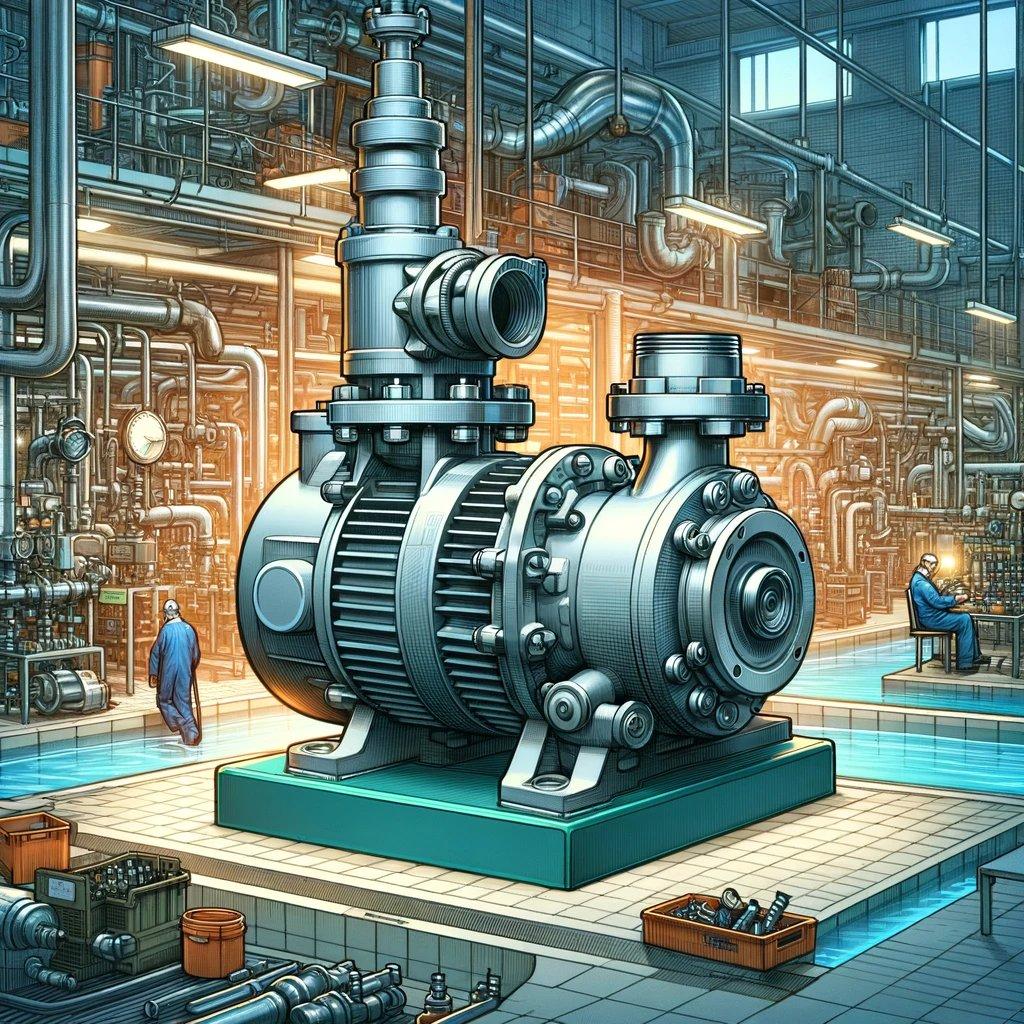

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Replacement Pumps

Replacement pumps play a key role in the renewal and modernization of industrial liquid and gas pumping systems. They are reliable and efficient equipment that can significantly increase the productivity and efficiency of production processes.

Advantages of industrial replacement pumps

Industrial replacement pumps are characterized by high performance and reliability. They are capable of pumping various types of liquids, including aggressive media and highly viscous liquids, making them a versatile solution for a wide range of industrial applications.

Replacement pumps: areas of application

These pumps are widely used in various industries, including chemical production, oil and gas industry, energy, food industry and many others. They can be used both to replace failed pumps and to modernize existing pumping systems.

Choosing replacement pumps

When choosing a replacement pump, it is necessary to take into account the requirements of the specific production process, the characteristics of the working environment and the characteristics of the materials being pumped. It is also important to pay attention to the performance, reliability, energy efficiency and maintenance of pumping equipment.

Industrial replacement pumps: reliability and durability

Industrial replacement pumps are made of high-quality materials and undergo strict quality control. They have a long service life and reliable operation even under conditions of increased loads and aggressive environments.

Conclusion

Replacement pumps are an important link in the renewal and modernization of industrial systems. The choice of appropriate pumping equipment significantly affects the efficiency and productivity of production processes, as well as the overall economic efficiency of the enterprise.