Pumps for Water jet cleaning

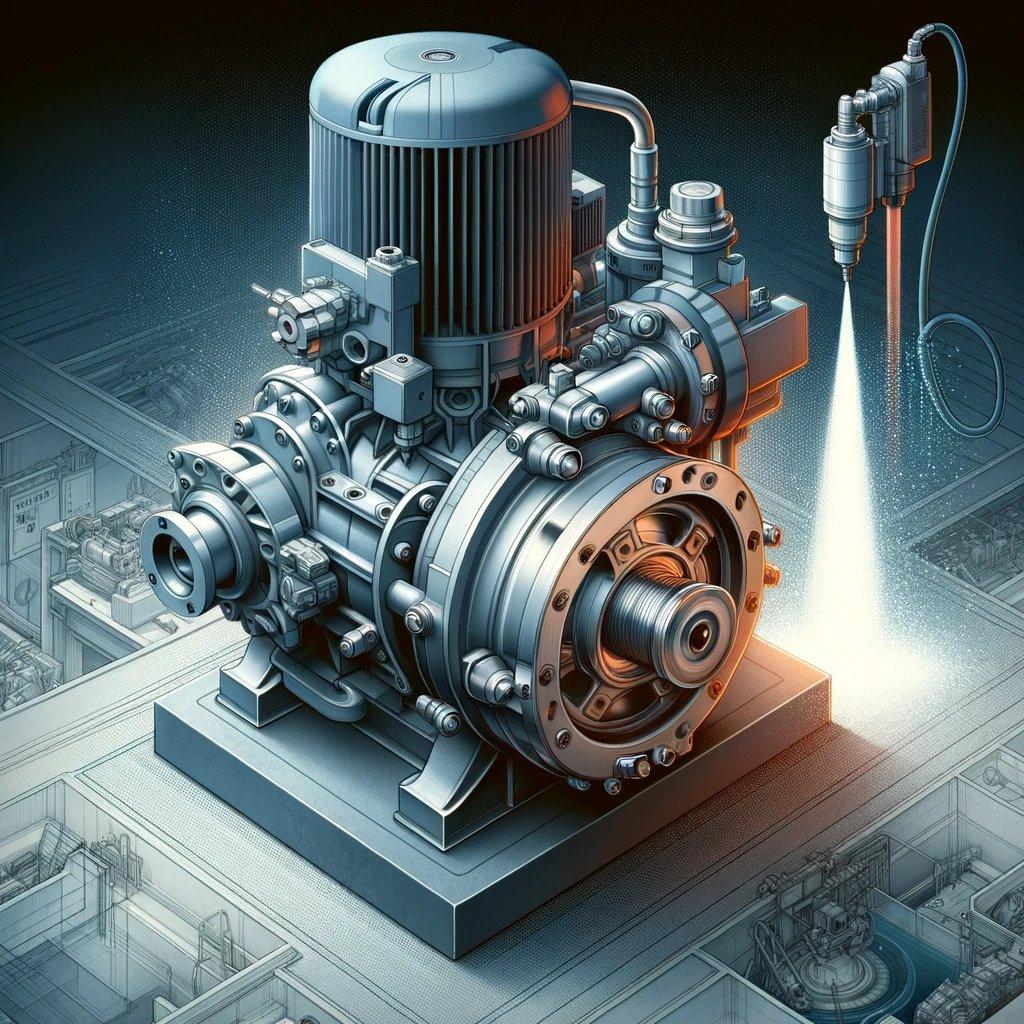

Waterjet pumps are specialised devices used to create the high water pressure required to drive waterjet cutting machines. These pumps play a key role in the waterjet cutting process by ensuring that materials such as metal, stone, glass and composite materials are separated accurately and efficiently. Waterjet cutting pumps are highly productive and reliable, making them an integral part of industrial and manufacturing processes that require precise and high-quality cutting of materials of any complexity and thickness.

TOP Pumps for water jet cleaning + other products

Waterjet Cutting Pumps: Features and Applications

Waterjet cutting pumps are important equipment used in various industries for precise and efficient separation of materials under the influence of high water pressure. These pumps provide high-pressure water to waterjet cutting tools, creating a strong water stream capable of cutting a variety of materials, including metal, stone, glass, and composite materials.

Advantages of industrial waterjet cutting pumps

- High performance: industrial waterjet cutting pumps have high performance, which allows you to quickly and efficiently cut materials of any thickness and complexity;

- Precision and quality: thanks to precise control of high water pressure, the pumps provide a high degree of accuracy and cutting quality, which is especially important for industrial and engineering applications;

- Versatility: waterjet cutting pumps can be used to process various materials, which makes them a versatile tool in various industries;

- Reliability and durability: industrial pumps are made of high-quality materials and have a durable design that ensures their reliable and durable operation;

- Economical: the use of water as a working medium makes the waterjet cutting process more environmentally friendly and economical compared to traditional cutting methods.

Choosing a Waterjet Cutting Pump

When choosing a waterjet cutting pump, there are several key factors to consider:

- Performance: Choose a pump with the appropriate capacity to meet your needs in terms of material cutting volume;

- Pressure: Estimate the water pressure required to effectively cut the material;

- Type of water source: Consider the possibilities of supplying water from different sources, such as a water supply system, a tank or a well;

- Power and energy efficiency: Choose a pump with optimal power and energy efficiency to minimize electricity costs;

- Technical support: Pay attention to the availability of technical support and service from the manufacturer, which will ensure reliable and uninterrupted operation of your equipment.

By choosing the right waterjet cutting pump, you will ensure efficient and high-quality performance of your material cutting tasks, which will increase the productivity and efficiency of your production.