Pumps for Recirculation

Recirculation pumps are specialised devices used to circulate liquids in various systems and processes. They provide continuous fluid movement in a closed loop to maintain certain system operating conditions. Industrial recirculation pumps are used in many industries, including water treatment, equipment cooling, and heating and air conditioning. They are available in a variety of types and configurations, including centrifugal, submersible and screw pumps, and the choice of which option to use depends on the requirements of the specific process and the characteristics of the process medium. The use of recirculation pumps helps to optimise system performance, increase process efficiency and ensure equipment stability.

TOP-7 Pumps for recirculation + other products

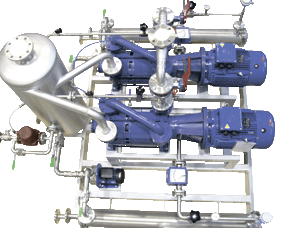

Liquid ring vacuum pump systems & centralized units

Liquid ring vacuum pump systems designed to meet most needs of vacuum of the industry. Developed with one or more pumps acting in parallel depending on the specific needs, the systems are equipped with dedicated equipment for service liquid cooling and recirculation including instrumentation and devices for control and full remote automatic operation including control panel with PLC and VFD. Units for hazardous area, on request.

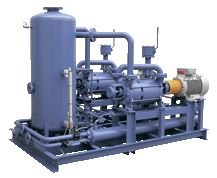

Heavy duty & API 681 liquid ring vacuum pumps & systems

Liquid ring vacuum pumps and systems meeting API 681 standards for chemical and petrochemical applications. Suitable for heavy duties, are available in different exotic materials with single or double cartridge API 682 cartridge mechanical seals. Package design standards in line with most stringent project specifications and quality requirements.

Liquid ring pump condenser exhausters

Liquid ring vacuum pumps are used in centralised vacuum systems and in power generation. The vacuum systems consist of exhaust ventilation units for the main condenser and filling units for the water condenser. The systems are designed for both load and hold modes.

In many cases, the pump is assisted by a first stage gas or steam ejector to improve pump performance at different condenser loads. The ASCO VACUUM team has extensive experience in geothermal applications.

Liquid ring pump hybrid systems

Hybrid systems offer the engineering advantage of designing process vacuum systems based on a combination of two or more different technologies to achieve the required performance with the most reliable and efficient solution.

Semi-welded plate heat exchangers SIGMADUAL

SIGMADUAL heat exchangers are the latest and most efficient device for transferring heat energy from a source to a destination, which can also be used for cooling purposes. Both liquids (preferably non-freezing) and gaseous substances can move in the channels of the corrugated plates as a working medium.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Recirculation Pumps

Recirculation pumps are important equipment used to circulate fluids in various technical systems. They play a key role in maintaining certain operating conditions and ensuring the efficient functioning of the system. Here are some key points to consider when choosing a recirculation pump.

Efficiency and Performance

Industrial recirculation pumps must be efficient and provide the required performance for a specific process. When choosing a pump, it is important to consider its capacity, fluid flow rate, and other specifications to ensure that it meets the requirements of the system.

Pump Type

There are several types of recirculation pumps, each with its own features and advantages. Centrifugal pumps provide high flow and pressure, submersible pumps are suitable for working with liquids at depth, and screw pumps provide a smooth and uniform flow. The choice of pump type depends on the requirements of a particular process.

Materials and Strength

When choosing a recirculation pump, it is important to pay attention to the materials of manufacture and its strength. The pump should be made of corrosion-resistant materials to ensure a long service life and minimal maintenance costs.

Reliability and safety

Industrial recirculation pumps must be reliable and safe to operate. They must meet all the necessary standards and certifications, as well as have protection functions against overloads, overheating and other emergency situations.

Cost and maintenance

When choosing a recirculation pump, you should consider not only its purchase price, but also the costs of its maintenance and operation. It is important to choose equipment that is economical to use and does not require frequent repairs.

As a result, the correct choice of a recirculation pump plays an important role in ensuring the efficiency and reliability of technical systems. When choosing a pump, it is necessary to take into account its technical characteristics, type, materials of manufacture, as well as its cost and maintenance.