Pumps for Distribution

Distribution pumps play a key role in a variety of industrial, agricultural and construction applications to ensure the efficient movement of liquids, bulk materials and other media. These industrial pumps can be used to distribute water, fuels, chemicals, fertilisers and other liquid and gaseous media, as well as to move grain, cement, sand and other bulk materials. Due to the variety of types and configurations, distribution pumps can be adapted to different conditions and requirements, ensuring reliable and efficient operation in a wide range of applications.

TOP-12 Pumps for distribution + other products

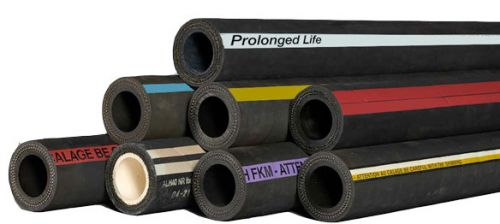

Hoses

We offer a wide range of hoses for peristaltic pumps. Our hoses are specially designed to last longer and perform better than the competition, resulting in reduced maintenance and downtime. The type of polymer and mechanical properties of the hose are the main factors for proper pump operation. The performance of a hose is determined by its elasticity, long-term resistance to compression and its chemical compatibility with the fluid being pumped.

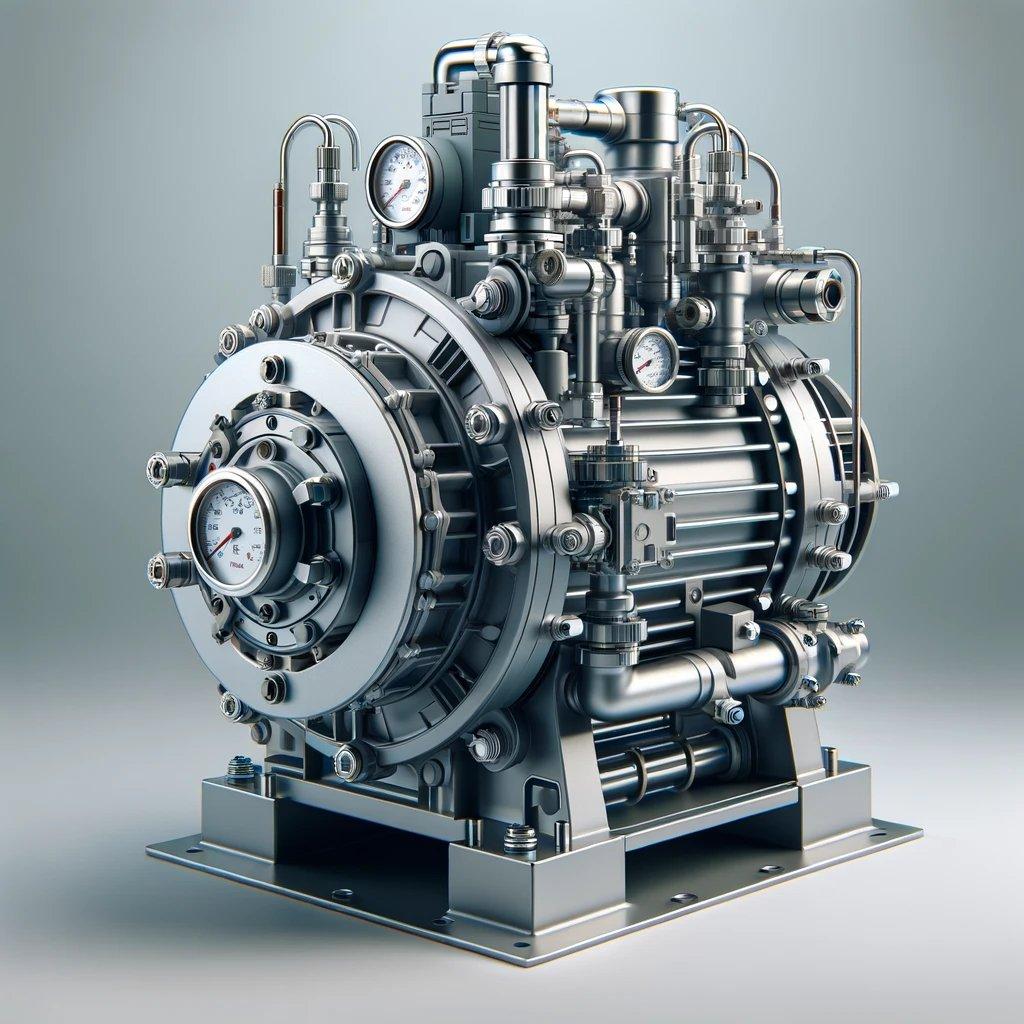

Heavy duty & API 681 liquid ring vacuum pumps & systems

Liquid ring vacuum pumps and systems meeting API 681 standards for chemical and petrochemical applications. Suitable for heavy duties, are available in different exotic materials with single or double cartridge API 682 cartridge mechanical seals. Package design standards in line with most stringent project specifications and quality requirements.

Hygienic Series

Pneumatic diaphragm pumps of the hygienic series are made of polished stainless steel AISI 316L. The pumps are hermetically sealed, self-priming, and are designed primarily for pumping of slightly aggressive media, food and cosmetic products. They are used in those industries where there are increased requirements to hygiene, for example dairy production.

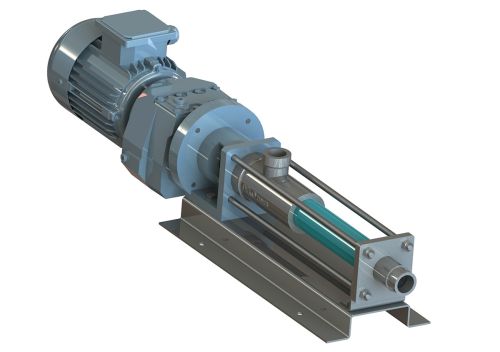

Screw dosing pump

Helical gear pumps

Helical gear pumps are used for pumping viscous liquids at low speeds. These pumps work same gear pumps. Pump shaft transmits circular movement with own gear to other gear on inverse side. While gears leave from other, liquid get full between gears. While gears become close, this liquid moves with rotary motion to outlet. We can have pressure until 20 Bar according to liquid viscose.

Also they are good in where there is a need for uninterrupted capacity for less viscous and medium pressure places.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Rotary lobe pump R

The R-series pump is ideal for the type of application where pumps with metal rotors will not work effectively. When you need to strip clean your pump because the product will not wash out by using a normal CIP process such as meat processing, the R pump overcomes this problem by its simple robust design. The R pump design utilities a floating rotor without rotor nuts. Rotors are interchangeable and can only be fitted in one position due to a specially modified square shaft.

Sinus Sodial Pumps

SOMA SINUS SODIAL® is a positive displacement pump. The peculiarity of the pumps is that the chambers are a single unit during movement, and their volume does not change during the pumping process; therefore, the pumped medium is not subjected to any significant mechanical stress. Due to the minimal deformation of the liquid, the pump is capable of pumping highly viscous substances.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

PTO/PQO/PSO series

The pumps of the PTO-PQO-PSO series comply with API 674 and ASME standards and are specifically designed and manufactured for process applications where continuous heavy duties are involved, demanding highest operating reliability and longest maintenance intervals.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Distribution Pumps: An Effective Solution for Your Business

Industrial Distribution Pumps: An Overview of Key Features

Industrial distribution pumps play an important role in many industries where precise and reliable movement of various media is required. These pumps have a number of key features that make them an excellent choice for a wide range of applications.

Distribution Pump: Key Benefits of Using

Choosing a distribution pump ensures efficient and uniform distribution of liquids or bulk materials, which is essential for maintaining high-level production processes. The main advantages of such pumps include:

- Accuracy: Dispensing pumps provide precise dosing and movement of the medium, which is especially important in industrial processes that require high accuracy and control.

- Reliability: Industrial dispensing pumps are made of high-quality materials and have a robust design, which ensures a long service life and minimal chance of failures.

- Productivity: Dispensing pumps are able to handle large volumes of liquids or materials in a short period of time, which increases the productivity of the process.

- Adaptability: These pumps can be adapted to different operating conditions and customer requirements, making them suitable for a wide range of applications in different industries.

Selecting a distribution pump: key criteria

Selecting a distribution pump: key criteria

When selecting a distribution pump, several important criteria must be considered to ensure optimal performance and reliability:

- Type of medium being pumped: The choice of pump type depends on the characteristics of the pumped medium, including its viscosity, density and aggressiveness.

- Performance: It is necessary to determine the required volume of pumped medium per unit time to select a pump with the appropriate performance.

- Pressure and head: Consider the pressure and head requirements that the pump must provide during operation.

- Materials and construction: Choose pumps made of high-quality materials, taking into account the characteristics of the medium and operating conditions.

Overall, distribution pumps are a reliable and effective solution for ensuring uniform distribution of various media in industrial processes. Choosing the right pump that takes into account the specifics of your production and process requirements will increase the efficiency and reliability of your equipment.