Pumps for metal casting

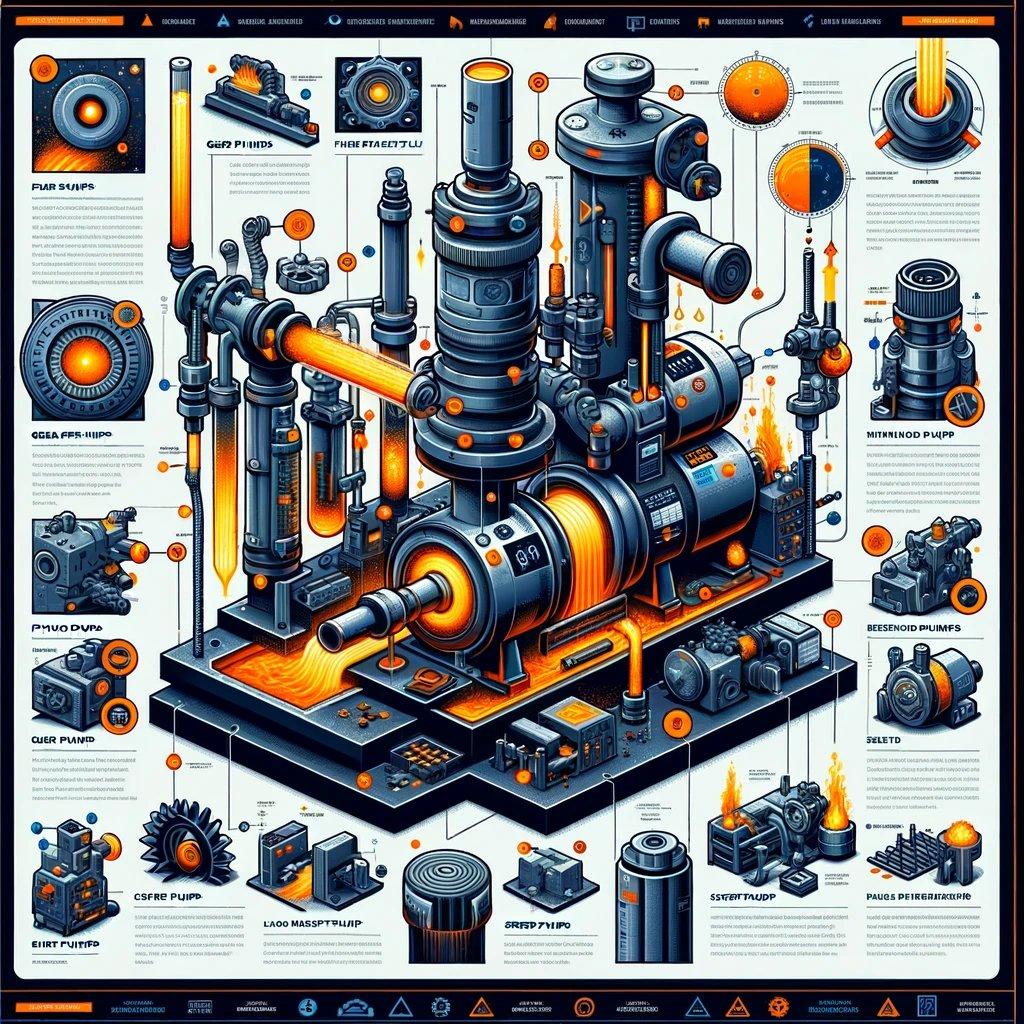

Metal tempering pumps are specialised devices used in the metallurgical industry to pump molten metals during the tempering process. They play a key role in the moulding of metal products by ensuring a continuous process of metal tempering and moulding. Metal tempering pumps must be specially designed to handle the high temperatures and aggressive chemical environments that are typical of the tempering stage. Their efficiency and reliability are critical to ensuring the quality and stability of the metal tempering process, which in turn affects the quality of the metal products produced.

TOP-1 Pumps for metal casting + other products

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Metal Tempering Pumps: Importance and Applications

Metal tempering pumps play a key role in the metallurgical industry, ensuring the efficient pumping of molten metals during their tempering process. These specialized devices are necessary to support the continuous process of forming and tempering metal, which is an important stage in the production of metal products.

Advantages of industrial pumps for metal tempering

- Reliability: industrial pumps for metal tempering are made of high-quality materials and have a durable design, which ensures their reliable operation in conditions of high temperatures and aggressive chemical environments;

- High performance: they are able to provide high performance of pumping molten metals, which is important for maintaining high efficiency of the production process;

- Adaptation to conditions: pumps for metal tempering are specially designed to work with high temperatures and aggressive environments, which allows them to function effectively in metallurgical workshops;

- Technical support: most manufacturers provide a wide range of services for technical support and maintenance of pumps, which ensures their reliable and durable operation. work.

Choosing a pump for metal tempering

When choosing a pump for metal tempering, you should pay attention to several key parameters:

- Type of metal: consider the type of metal being pumped, as different metals require different approaches to pumping;

- Required performance: determine the required pump performance according to the needs of your production;

- Technical characteristics: consider the features of the technological process and the requirements for the pump, such as maximum pressure, temperature and chemical compatibility with the pumped medium;

- Manufacturer's reputation: choose pumps from reliable manufacturers with a good reputation, which will ensure the quality and reliability of the equipment.

By choosing the right pump for metal tempering, you will ensure reliable and efficient operation of your metallurgical production.