Pumps for Settling

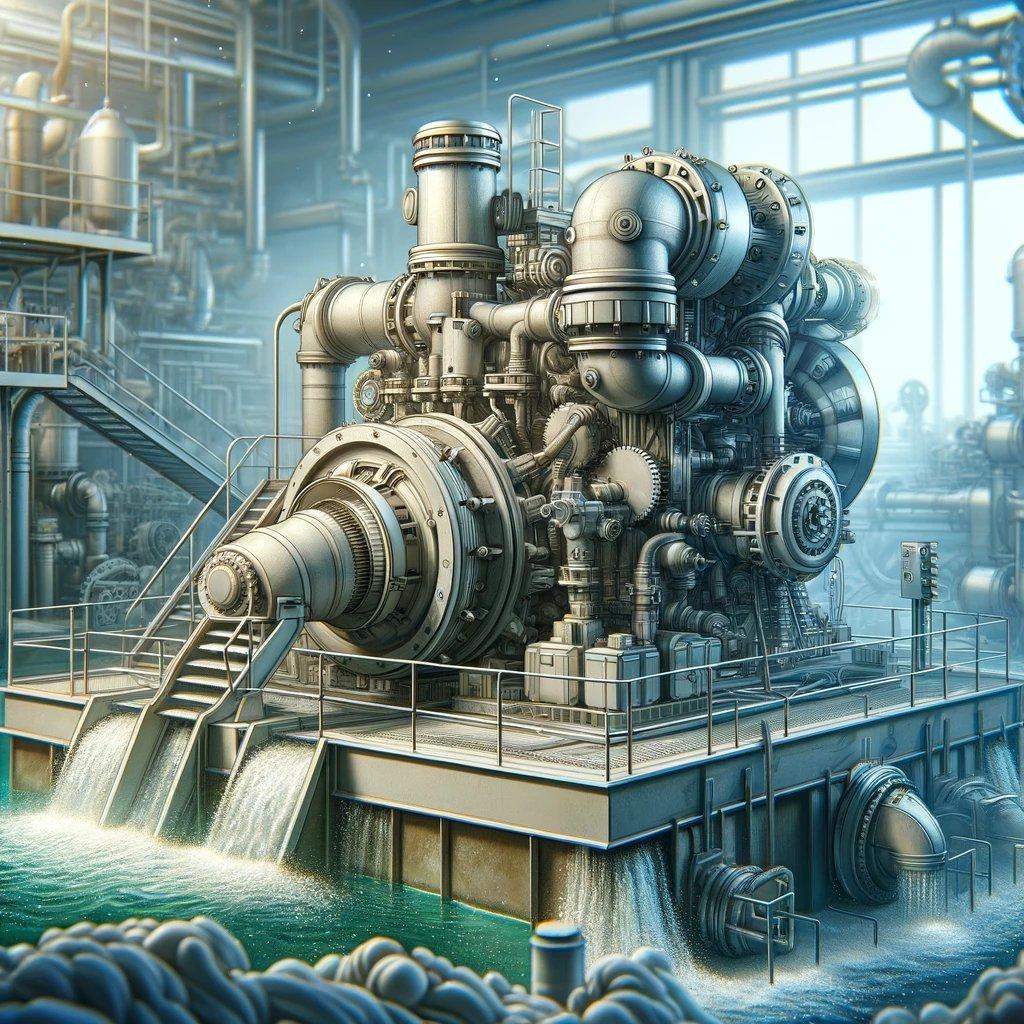

Settling pumps are an important component in the treatment of wastewater and aqueous solutions. They are designed to pump settled particles or sludge from one location to another in the treatment system, ensuring effective removal of solid sediments from the water. Industrial sludge pumps have high performance and reliability, making them an essential piece of equipment for wastewater treatment plants, wastewater treatment plants and industries where effective waste management is required. Settling pumps are available in a variety of types including centrifugal, vortex, submersible and peristaltic, and the choice of a particular model depends on the requirements of the particular treatment process and operating conditions. They have special design features, such as large inlet diameters and enlarged cross-sections, to ensure efficient sludge movement without clogging or loss of performance. Settling pumps play a key role in the smooth operation of water treatment systems and are an essential element in environmental protection and water conservation.

TOP-2 Pumps for settling + other products

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Horizontal centrifugal pumps

Idrochemical NCM centrifugal pumps comply with the dimensional criteria of ISO 2858 and ISO 5199. The casing and impeller profiles are designed to achieve high hydraulic efficiency and low NPSH.

The NCM line is available in five bearing housing sizes with wide interchangeability of parts, which allows for low maintenance spares.

Sedimentation Pumps: An Effective Solution for Wastewater Treatment

Applications of Sedimentation Pumps

Sedimentation pumps play a key role in the treatment of wastewater and aqueous solutions in industrial and municipal systems. They are used to pump settled particles or sludge from one place to another in treatment systems, ensuring the effective removal of solid deposits from water.

Features of industrial sedimentation pumps

Industrial sedimentation pumps have high performance and reliability, which makes them an integral part of the equipment for wastewater treatment plants, treatment facilities and industries where effective waste management is required.

Types of sedimentation pumps

Sedimentation pumps can be of various types, including centrifugal, vortex, submersible and peristaltic. The choice of a specific model depends on the requirements of the specific treatment process and operating conditions. They have special design features such as large inlet diameters and increased flow cross-sections to ensure efficient sediment movement without clogging or loss of performance.

Advantages of sedimentation pumps

The use of sedimentation pumps allows for the smooth operation of water treatment systems, reduces the risk of contamination and damage to equipment, and improves the quality of treated water. They play an important role in environmental protection and water conservation, contributing to the sustainable development of industry and the municipal sector.

Selecting a Sedimentation Pump

When selecting a sedimentation pump, factors such as performance, sediment type and particle size, water pressure and flow rate, as well as the specifics of the specific treatment process must be taken into account. Consulting with experienced specialists and professionals in the field of water treatment will help you choose the optimal solution for specific needs.

Conclusion

Sedimentation pumps are an integral part of water treatment systems, ensuring effective removal of solid deposits and ensuring a high level of purification of wastewater and aqueous solutions. Choosing the right pump and its proper operation play an important role in ensuring stable and reliable operation of treatment plants and industrial processes.