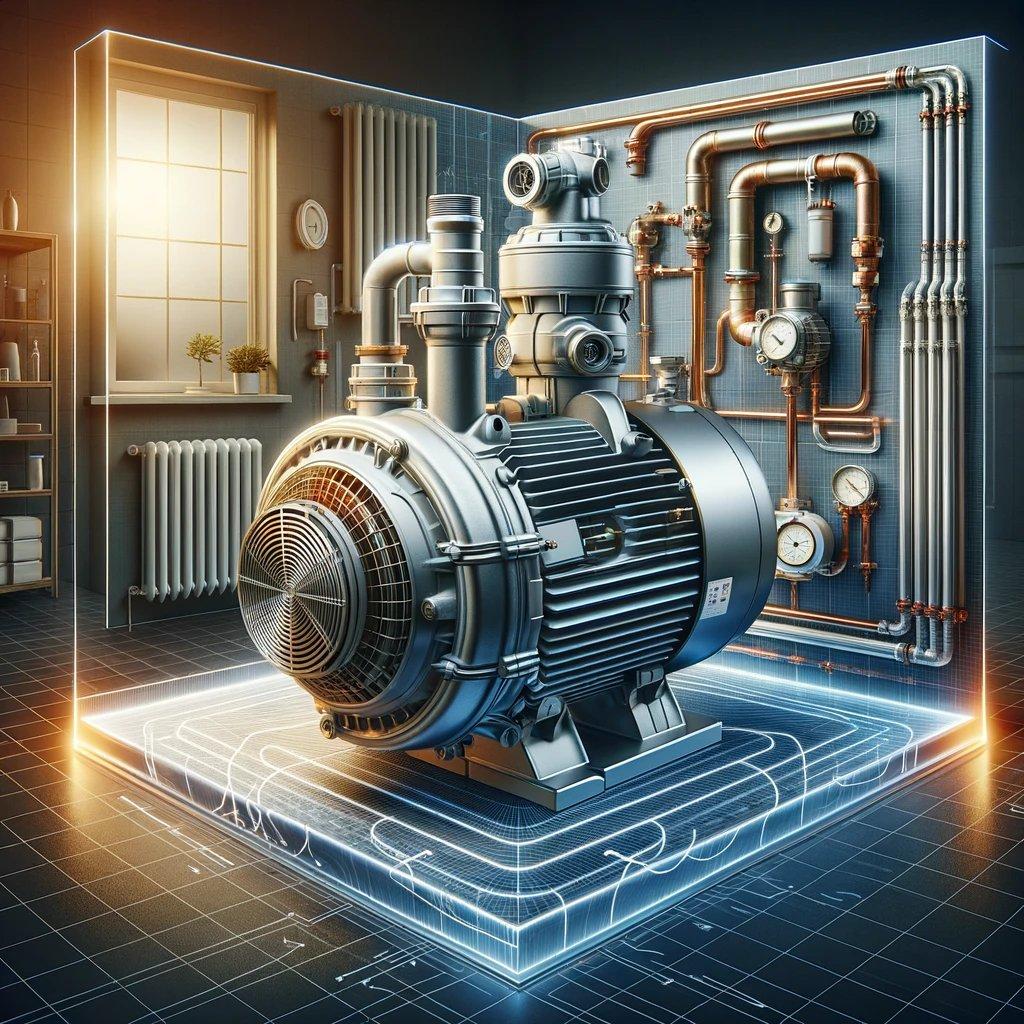

Pumps for Heating

Heating pumps are specialised devices designed for pumping heat transfer fluid in heating systems, heat pumps, solar collectors and other technical installations where liquid or gas needs to be heated. They ensure efficient circulation of the heat transfer medium, maintaining the required temperature and ensuring even heat distribution throughout the system. Industrial heating pumps come in a variety of designs and features, including high performance, reliability and the ability to operate over a wide range of temperatures and pressures. Selecting the right pump for your application is essential to ensure efficient heating system operation and reduce energy costs.

TOP-7 Pumps for heating + other products

Tubular heat exchanger - ParaTube

In some cases, tubular heat exchangers are used for pasteurization and sterilization of dairy products. Unlike plate heat exchangers, these heat exchangers have no contact points in the product channel and can therefore be used to handle products whose particles are limited to a certain size. The maximum particle size depends on the pipe diameter. When operating in sterilization mode, a tube heat exchanger is less likely to need to be stopped for cleaning than a plate heat exchanger. In terms of heat transfer, a tube heat exchanger is less efficient than a plate heat exchanger.

Plate heat exchangers - sanitary version

Sanitary applications place unique demands on solids handling, product integrity, thorough cleaning, high efficiency and minimal downtime. With more than 60 different plate sizes to choose from, as well as technologies such as Energy-saver, Energy-saver+, Duraflow and Easyflow, APV ensures that your process requirements are met with the best possible solution. Solutions that minimise energy consumption by increasing heat transfer efficiency. Solutions that reduce plate fouling and provide easy equipment maintenance - all to minimise downtime and keep your process running smoothly.

Side Channel Blowers

Blowers are an excellent choice for many automated projects where the application requires large volumes of clean, dry air at low pressure and vacuum. We strive to provide a solution that allows for easy installation, yet provides low operating noise and energy savings in a small, lightweight design.

Semi-welded plate heat exchangers SIGMADUAL

SIGMADUAL heat exchangers are the latest and most efficient device for transferring heat energy from a source to a destination, which can also be used for cooling purposes. Both liquids (preferably non-freezing) and gaseous substances can move in the channels of the corrugated plates as a working medium.

Plate & shell heat exchangers SIGMASHELL

SIGMASHELL heat exchangers are a unique combination of the strength and high pressure capability of shell-and-tube heat exchangers with the compactness and high thermal efficiency of plate heat exchangers.

Gasketed plate heat exchangers SIGMA

SIGMA plate heat exchangers have excellent design characteristics that ensure their durability and reliability. Plate heat exchangers use corrugated plates that are placed between a fixed and movable pressure plate. Due to the fact that almost all of the material is used for heat transfer, plate heat exchangers have a large effective heat transfer area with a minimum of space. Often, a plate heat exchanger can deliver the same heat transfer capacity as a shell-and-tube heat exchanger that is five times larger in volume.

All-welded plate heat exchangers SIGMAWIG

The line of Schmidt SIGMAWIG all-welded plate heat exchangers represents the most compact, rugged and cost-effective means of transferring heat in many demanding industrial applications.

This is a new level of application for heat exchangers for special applications in the chemical and pharmaceutical industries, industrial cooling systems and heat balance systems.

Heating pumps

Efficiency and reliability

Heating pumps are key components in heating systems, ensuring the circulation of the coolant and efficient heat exchange. They play an important role in maintaining a comfortable temperature in the room or providing heat in industrial processes. Industrial heat pumps are designed to operate in a variety of conditions and can withstand high temperatures and pressures, making them a reliable choice for a wide range of applications.

Variety of models and types

There are many models of heat pumps on the market, including circulation pumps, peristaltic pumps, screw pumps, and others. Each type of pump has its own characteristics and advantages, which allows you to choose the optimal solution for a specific task.

Choosing the right pump

When choosing a heat pump, you need to consider parameters such as performance, maximum operating pressure, material of the housing and working elements, energy efficiency, and maintenance costs. Professional consultants can help determine the best option depending on specific requirements and operating conditions.

Benefits of using industrial heat pumps

Industrial heat pumps are characterized by high performance, durability, and reliability. They are able to work in extreme conditions and ensure stable operation of the system for a long time without failures and interruptions.

Energy efficiency and resource saving

Energy efficiency and resource saving

Modern heat pumps have high energy efficiency and can significantly reduce the energy consumption of the heating system. This allows you to save on electricity costs and reduce the load on the energy infrastructure.

Quality guarantee and service support

When choosing a heat pump, it is important to pay attention to the manufacturer's reputation and the warranty obligations provided. High-quality pumps are usually accompanied by a long warranty period and the availability of service support, which ensures the reliability and safety of equipment operation.

Conclusion

Heating pumps are an important link in heating systems and industrial processes, ensuring effective circulation of the coolant and uniform heat distribution. Choosing the right pump plays a decisive role in ensuring the efficient operation of the system and saving resources. Professional consultants and high-quality technical support will help you make the right choice and ensure reliable operation of the equipment for many years.