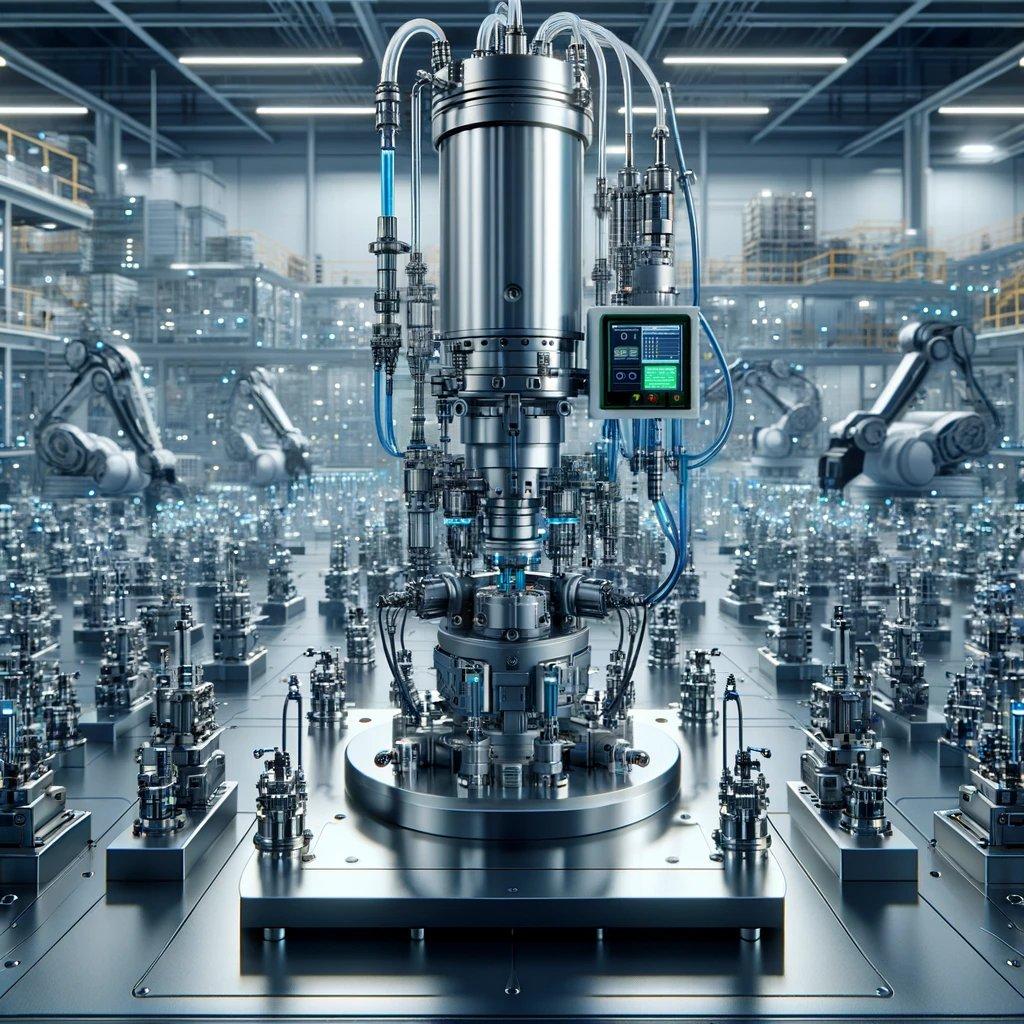

Pumps for Pressurisation

Sealing pumps are specialised devices designed to create and maintain pressure in systems that require a tight seal, such as heating, air conditioning, water supply and industrial processes. They ensure reliable system operation by creating the necessary pressure to seal pipework, fittings and seals. Sealing pumps are widely used in industry and construction to ensure the safety and reliability of technical systems and processes.

TOP-6 Pumps for pressurisation + other products

Single stage liquid ring vacuum pumps AVM & AVL

The AVM and AVL series consist of single-stage liquid ring vacuum pumps designed to achieve deep vacuum. Both series have the same hydraulics but different designs.

Single stage liquid ring vacuum pumps AVA

The AVA series pumps are designed and manufactured for use in the most critical applications, their main feature being that they are suitable for suction of contaminated gas mixtures, corrosive gases and vapours, explosive gases and vapours of any nature up to normal end vacuum, providing a maximum vacuum of up to 180 mbar. They are manufactured to the highest quality standards.

Two-stage liquid ring vacuum pumps of the AVD series

Two-stage vacuum pumps of the AVD-AVDL series are capable of creating a maximum residual pressure of up to 33 mbar. They are in demand in cases where it is necessary to pump out various moisture in the form of steam or liquids in sufficiently large quantities. The reliability of the products is beyond doubt, they are easy to maintain, and they can be used to pump out any gas or vapour. Materials used for manufacturing range from high-quality, particularly resistant cast iron to stainless steel of the highest grades, for example, AISI 316.

Oil rotary vane vacuum pumps AVPL

The AVPL oil rotary lobe pumps are extremely compact thanks to their integrated motor and transmission, making them the ideal choice for compact installations. They are equipped with extremely robust blades that ensure a long service life. Specially designed oil filters ensure excellent oil separation, removing even the smallest oil droplets from the exhaust air.

Dry-operated rotary vane vacuum pumps AVPS

Dry operated rotary vane pumps designed to operate without any lubrication. They require minimum maintenance, which can be carried out easily thanks to the direct access to the vanes. They can be used as vacuum pumps, as compressors, or to produce vacuum and pressure simultaneously.

General industrial gear pumps

General purpose pumps are widely used in all areas of industrial production around the world due to their gentle handling of the fluid during pumping, as well as their simple and robust design and minimal maintenance. Thanks to the standard connection dimensions, the pumps can be combined with any motor and other drive elements that comply with NEMA or IEC standards.

Sealing Pumps: An Overview

Sealing pumps are an important element in systems that require reliable sealing, such as heating, air conditioning, water supply and industrial processes. They play a key role in ensuring the reliability and safety of technical systems, creating and maintaining the necessary pressure for the tight connection of pipelines, connecting elements and seals.

Advantages of industrial pumps for sealing

- Reliability: industrial pumps for sealing have a high degree of reliability, which ensures safe and uninterrupted operation of technical systems;

- Efficiency: they ensure the effective creation and maintenance of the necessary pressure in the system, which reduces the risk of leaks and increases operational efficiency;

- Versatility: pumps can be used in various industries and construction to seal various systems and processes;

- Ease of maintenance: most pumps have a simple design and are easy to maintain, which simplifies their operation and increases their service life;

- Economy: the use of reliable of sealing pumps helps reduce maintenance and repair costs of systems, making operation more economical.

Choosing a Sealing Pump

When choosing a sealing pump, you should consider a number of key factors:

- Required performance: determine the volume and pressure that are required to seal your system;

- Type of material used: consider the chemical and physical properties of the liquid or gas that is pumped by the pump;

- Brand and manufacturer: give preference to proven and reliable manufacturers to be sure of the quality and durability of the pump;

- Technical support: pay attention to the availability of a warranty and service from the manufacturer to ensure the reliability and uninterrupted operation of the pump.

By choosing the right sealing pump, you can ensure the reliable and safe operation of your technical system and increase the efficiency of your production.